RESEARCH ARTICLE

The Research of Procyanidins Extracting and Membrane Concentration Efficiency Based on Ultrasonic -Assisted Filtration

Rongbiao Zhang*, Dongmin Ning, Liang Qiu, Yang Qian, Zuowei Ren

Article Information

Identifiers and Pagination:

Year: 2016Volume: 10

First Page: 239

Last Page: 247

Publisher ID: TOBIOTJ-10-239

DOI: 10.2174/18740707016100100239

Article History:

Received Date: 18/9/2015Revision Received Date: 9/2/2016

Acceptance Date: 19/3/2016

Electronic publication date: 31/05/2016

Collection year: 2016

open-access license: This is an open access article licensed under the terms of the Creative Commons Attribution-Non-Commercial 4.0 International Public License (CC BY-NC 4.0) (https://creativecommons.org/licenses/by-nc/4.0/legalcode), which permits unrestricted, non-commercial use, distribution and reproduction in any medium, provided the work is properly cited.

Abstract

In order to improve the traditional methods of procyanidins extracting, ultrasonic-assisted filtration was used in the process of extracting proan-thocyanidin which was from membrane concentration of grape seed. Through the mechanism analysis of ultrasonic-assisted ultrafiltration, ultrasonic is able to alleviate the phenomenon of concentration polari-zation, so the efficiency of extracting proanthocyanidins was improved. Based on the phenomenon that ultrasonic enhanced membrane concentration of procyanidins extracting, BP neural network was used to construct the ultrasonic-assisted filtration membrane-flux model, and the genetic algorithm was used to optimize the parameters of ultrasonic-assisted filtration. The research results show that the optimal process parameters of ultrasonic-assisted are ultrasonic power 240W, number of vibrator 6, angle of vibrator 40°and ultrasonic time 9 min. Itrafiltration flux increased by 42% under the above conditions.

1. INTRODUCTION

Procyanidins have received growing attention because of the powerful function of antioxidant, resisting arteriosclerosis, antithrombotic, antitumor and skin care. Procyanidins exist extensively in plant cell, especially in grape seed .About 300000 tons grape seed are discarded as waste because of the thick hard husk each year in china. So the deep study of procyanidins extracting process is important to utilize grape seed resources rationally and improve the added value of agricultural products.

Solvent extraction is a conventional method of procyanidin extraction, while the time of extraction process is too long and the efficiency is very low. And hot solvent may cause the degradation of procyanidin easily and the decrease of physical activities.

Membrane concentration technology is a typical application of membrane separation method, compared with traditional hot concentration method, it has the advantages of low working temperature, small thermal decomposition and low risk of degeneration, no phase change, low energy consumption, etc. [1]. There has been related research on the extraction of polyphenols active natural products with membrane concentration technology [2]. Clarification and concentration of red cabbage anthocyanin using ultrafiltration, nanofiltration and reverse osmosis membrane technology are studied by Zhen-zhen Xu [3]. But the contaminant and clogging of membrane surface result in the phenomenon of concentration polarization and reducing membrane separation efficiency. Lots of scholars in and abroad have combined membrane separation technology with ultrasound in order to solve the problem caused by membrane fouling and concentration polarization, for example, Ultrasound field enhanced PAN membrane filtration was studied by Takaomi Kobayashi etc. [4].

Effects of ultrasound on ultrafiltration of radix astragali extract and cleaning of fouled membrane was studied by Cai etc. [5]. Effect of ultrasound on the separation of binary protein mixtures by cross-flow ultrafiltration was reported by Teng etc [6]. However, the application of the combined ultrasound and membrane separation technology to ultrafiltration concentration of procyanidins has reported rarely.

In this paper, the technology of ultrasonic-assisted filtration is applied to the membrane enrichment process of extracting procyanidins. The structure of ultrafiltration concentration equipment is designed and the effect of ultrasound parameters on procyanidins extracting efficiency is analyzed. It takes membrane flux as index to detect the membrane enrichment efficiency, to determine the optimum process condition of ultrafiltration.

2. MECHANISM ANALYSIS OF UL-TRASONIC-ASSISTED FILTRATION

2.1. Concentration Polarization and Mass Transfer Model

During the process of ultrafiltration separation, solute was accumulated on the surface of the membrane due to the interception of membrane, and the solute concentration around membrane surface is much higher than bulk solution. This phenomenon was described as concentration polarization. Usually with increasing concentration polarization, a significant reduction in flux as well as ultrafiltration efficiency take place. Solute will form a gel layer on the membrane surface when the membrane surface solute concentration exceeds a certain value. Membrane transfer process will be convert from the concentration polarization model to gel layer model.

Mass transfer model can be expressed as [7]:

|

(2.1) |

where k is the mass transfer coefficient, Cm(mg/L) is solute mass fraction of membrane surface, Cb(mg/L)is bulk solution mass fraction in feed.

According to the model, concentration polarization can be reduced by regulating the mass transfer coefficient, subsequently membrane flux has changed. Mass transfer coefficient can be described by Sherwood, that is Sh = kdh / D , and mass transfer coefficient can be described by LEVEQUE equations under the laminar flow state:

|

(2.2) |

In which Re = dk u / v and Sc = v / D

Where v(m/s) is kinematic viscosity, dh(m)is hydrodynamic diameter, u (m2/s)is flow velocity, L(m) is the length of membrane tube, D is diffusion coefficient. The main influential factors of mass transfer coefficient were flow rate, solute diffusion coefficient, viscosity, the shape and specifications of the membrane module, etc. However the solute diffusion coefficient was influenced by the temperature, osmoatic pressure and mass number of feed, but the ultrasound can improve the factors which influence the mass transfer coefficient, further enhanced ultrafiltration process, improve membrane flux.

2.2. Design of Experiment System

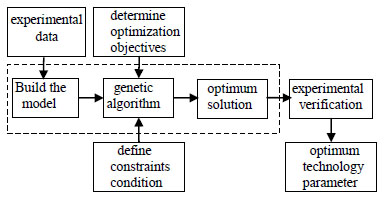

The whole project of the optimizing parameters of the filter based on the ultrafiltration performance is shown in Fig. (2.1).

|

Fig. (2.1). The design of system function. |

Membrane flux is used as the optimization objective. Secondly, the optimized ultrasonic field control parameters and constraints are determine. At last, the membrane separation of the membrane separation is used to optimize the model and the genetic algorithm is used to solve the model. Determine the optimum process parameters of ultrasonic assisted filtration.

2.3. Analysis Parameter of Ultrasound-Assisted Filtration

The strengthening effects of ultrasound on membrane separation process associate with several factors such as ultrasound field parameters( frequency, intensity and direction of propagation), operating parameters(time, temperature, pressure, flow velocity), membrane material and structure and so on. Than ultrasound parameters briefly analyzed as following.

2.3.1. Ultrasound Frequency

When ultrasonic intensity is certain, the lower the ultrasonic frequency, the more prone in the liquid cavitation; for the high frequency ultrasound, because of thinned solution and increased frequency compression, cycle time become shorten and the cavitation bubble is too small to achieve the object of disturbing the solution. Despite lots of cavitation bubble bursting in unit time, the energy produced by bubble bursting is not enough to take away the particles on the membrane surface, so the performance of filter membrane decreased [8]. Ai jianqiang has studied that compared the frequency of 30 KHZ and 800 KHZ ultrasonic on the effect of methylene blue through a semipermeable membrane, the result prove that the effect of frequency of 30 KHz ultrasound is better than frequency of 800 KHz [9].

2.3.2. Ultrasonic Intensity

Ultrasonic intensity refers to the ultrasonic power per unit area, the intensity power directly affects the effect of cavitation. In general, the more the intensity of ultrasonic, the greater the cavitation. Lamminen and other scholars considered that with the increase of ultrasonic intensity, the number and size of cavitation bubble increased, a stronger sound pressure formed at the same time [10]. The relationship of membrane flux and ultrasonic intensity is not a linear within a certain range, because the number of cavitation bubble is limited and part of the energy is converted into heat. Other scholars reported that the membrane flux would be decreased if the ultrasound is too high, because cavitation bubble would grows too fast even connects into pieces, so a barrier was formed on the surface of ultrasound source and prevents the spread of ultrasound waves. Thus, the membrane flux does not become better with the rise of ultrasonic intensity, but there exists an optimum value.

2.3.3. Direction of Propagation

Different directions of propagation affect the influence of ultrasound-assisted filtration. Kobayashi compared three different effects of three direction of propagation on membrane flux [11]. Firstly, the ultrasonic propagation direction perpendicular to membrane and consistent with the direction of water; secondly, the ultrasonic propagation direction perpendicular to membrane but in the opposite direction with water; thirdly, the ultrasonic propagation direction parallel to the membrane and perpendicular to the direction of the water. Research has found that the first case has the best effect on increasing membrane flux but the second case has the least effectiveness. It shows that the increased membrane flux not only depends on ultrasonic intensity, but also relates to the direction of propagation.

2.3.4. Ultrasonic Time

Ultrasound can effectively retrain concentration polarization and remove the filter cake layer resistance to improve membrane flux. Membrane flux is not always increasing with the extending of ultrasound time, so there has not a define value for the optimization of ultrasonic time. Muthukumaran and other scholars have studied the recovery of membrane flux with the methods of ultrasonic time was 10 minutes, 20minutes, 30mintues respectively. Ultrasound 10 minutes not worse than 20mintues and 30 minuets [12]. Jian xin and some scholars have studied that the effect of using ultrasound impact on membrane flux after 30 min is as well as 10 minutes [13]. The reason may be that the oscillator temperature increases with the operation, the sound energy decreased.

As a result of analysis above, the lower the ultrasonic frequency, the strength the more obvious effects of membrane filtration. So ultrasound oscillator frequency of the device is 28 KHz. Ultrasound intensity is the main parameters of the ultrasound field, and as far as this experimental study, the parameter of ultrasound intensity can be instead of the parameter of ultrasonic power and the parameter of the number of vibrator.

Fig. (2.2) shows ultrasound vibrator isomeric installed on the stainless steel shell, GH2500F30 organic roll film (outer diameter is 58.30mm and length is 97mm) is nested in the stainless steel shell. In order to make each section of membrane module can be under the effect of ultrasound field, ultrasonic vibrator should be installed equidistantly.

|

Fig. (2.2). The structure diagram of vibrators arrangement. |

3. MATERIALS AND METHODS

3.1. The Preparation of Procyanidins Extract

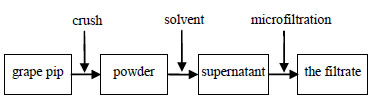

2Kg grape seed was crushed and sieved, and weighing accurately about 1Kg grape seed powder into 70% ethanol solution which solid to liquid ratio of 1:3. The procyanidins crude extract has prepared after stirring and extracting for 2 hours. Using ceramic microfiltration membrane to filter the procyanidins crude extract and after treatment 10 minutes under the condition of temperature and 0.5MPa to remove suspended solids and macromolecules colloidal substances of the procyanidins crude extract, then we can get procyanidins extract as raw materials for the enrichment (Fig. 3.1).

|

Fig. (3.1). The process flow diagram of procyanidins extract. |

3.2. The Experimental Facilities

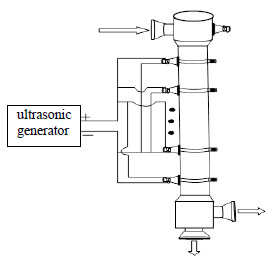

Membrane filtration system is mainly composed of ultrasonic pretreatment equipment, microfiltration ultrafiltration equipment and ultrasonic device. Through the structural design of these three parts, the final membrane separation of the ultrasonic filter aid equipment as shown in Fig. (3.2).

3.3. Determination of Membrane Flux

The membrane flux computation formula is as follows:

|

(3) |

Where J is the membrane flux, V(m3)is the volume of liquid which through the membrane, t(min)is ultrafiltration time, S(m2) is the effective area of membrane.

The volume of the filtrate was measured by electromagnetic flowmeter

|

Fig. (3.2). The equipment of membrane separation with ultrasonic. |

3.4. The Ultrasound Experiments

On the basis of ultrasound field parameters and experiment equipment, four ultrasound parameters were selected which will effect membrane flux: ultrasonic power P1(160W< P1<300W), number of vibrator N2(N2=4,5,6,7,8), oscillator angleα3(N2*α3<360)and ultrasound time T4(T4 =1,3,5,7,9,11,13,15min). Experiments were carried out 90 times by selecting appropriate conditions P1, N2, (3and T4, then getting 90 membrane flux J as experiment results. Partial experiment data are shown in Table 3.1.

Data of membrane flux of part sample.

| number | Ultrasonic power/W | Vibrator number | Oscillator angle/° | Ultrasound time/min | Membrane flux/LMH |

|---|---|---|---|---|---|

| 1 | 240 | 6 | 30 | 3 | 29.5 |

| 2 | 220 | 5 | 40 | 13 | 32.3 |

| 3 | 280 | 6 | 60 | 5 | 29.3 |

| 4 | 160 | 4 | 50 | 3 | 25.5 |

| : | : | : | : | : | : |

| 88 | 260 | 5 | 45 | 15 | 33.5 |

| 89 | 280 | 7 | 40 | 7 | 30.5 |

| 90 | 300 | 8 | 35 | 9 | 29.8 |

4. RESULTS AND ANALYSIS

4.1. Membrane Flux Model Based on Neural Network

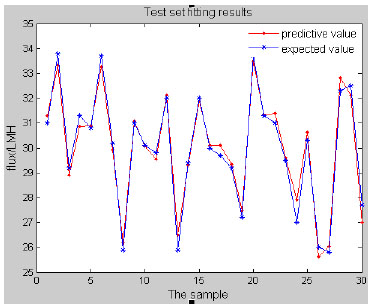

BP neural network overcomes the limitations of perceptron network and linear neural network and can achieve both arbitrary linear and non-linear function mapping.60 sets of data of ultrasonic ultrafiltration experiments were chose as the BP neural network training set to build model J = f (P1, N2, α3, T4). The remaining 30 sets of experimental data were used to fit the flux with the model .

After comparing it is found that when the number of hidden layer neurons is 9, fitting the data to be able to accurately whatever training set or test set. Therefore, selecting the topology for the 4-9-1 BP neural network which learning rate is 0.01, convergence accuracy is 10-6 and iterative times is 5000.

The fitting effect of the test set is shown in Fig. (4.1).

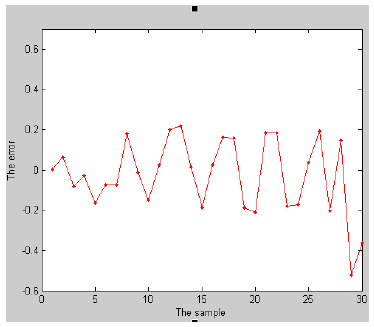

The error curves between the fitting membrane flux of the BP neural network and the experimental membrane flux are shown in Fig. (4.2).

From the results above it is indicated that the correlation coefficient is about R=0.9931, root-mean-square error is MSE=0.2772. In conclusion, the model established by BP neural network can achieve accurate prediction of the membrane flux.

|

Fig. (4.1). The fitting effect of flux model. |

|

Fig. (4.2). The prediction error of flux model. |

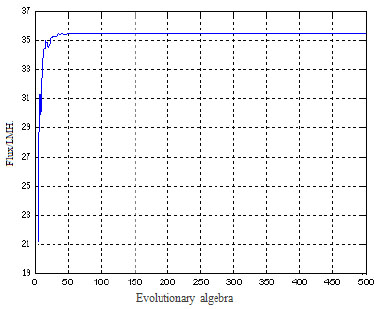

4.2. Genetic Algorithm Optimize Ultrafiltration Parameters

The mapping relationship between the ultrafiltration flux and 4 ultrasonic parameters (N2, P1, α3, T4) was fitted according to BP neural network, and the model established by BP neural network was used as the fitness function of genetic algorithm to conduct global optimization. The test set data is used as the initial population, the constraint condition is the parameter range of 4 ultrasonic parameters (N2, P1, α3, T4), and the objective is the maximum value of the fitness function. This method adopted binary encoding and the crossover probability is 0.7, the mutation probability is 0.05. Genetic toolbox is used on the MATLAB platform for simulation, the results of the simulation as shown in Fig. (4.3). The best fitness function value has reached its maximum after 500 times optimizing and then tends towards stable.

|

Fig. (4.3). The change curve of fitness value of membrane flux. |

The maximum of ultrafiltration membrane flux in theory is 35.56L/MH, the corresponding ultrasonic parameters as shown in Table 4.1.

Optimum ultrasonic parameters and membrane flux.

| Ultrasonic power/W |

Vibrator number |

Vibrator angle/° |

Ultrasonic time/min |

Membrane flux/LMH |

|---|---|---|---|---|

|

240 |

6 |

40 |

9 |

35.56 |

4.3. Experimental Verification

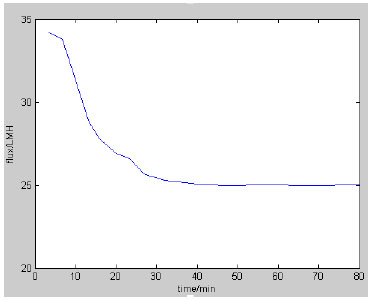

Before the ultrasonic enhanced ultrafiltration experiment, an experiment about the membrane flux changing with time on the condition of no ultrasonic field was carried out. The experimental results are shown in Fig. (4.4).

|

Fig. (4.4). The change curve of membrane flux with time. |

From Fig. (4.4) it is shown that in the initial stage of ultrafiltration (15min), the membrane flux decreased rapidly due to the push of the external pressure, the small molecules were trapped in the membrane. While dropping speed of the flux slowed owing to concentration polarization with the time going (15-35min). And the membrane flux was stable at about 25L/MH 40 minutes later.

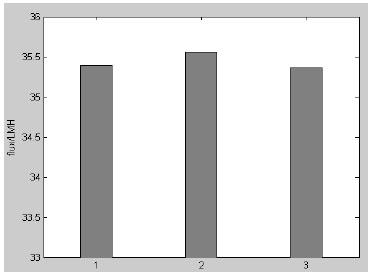

According to the 4.3 section, the optimal ultrasonic parameters were obtained by genetic algorithm. Three times experiments were conducted with these parameters and the results are shown in Fig. (4.5). The results indicated that the ultrafiltration flux reached 35.5 L/MH, and there was no significant difference between the experimental results and the theoretical values. And compared with the initial membrane flux of 25 L/MH, the membrane flux increased by 42%.

|

Fig. (4.5). The histogram of experiment membrane flux. |

CONCLUSION

(1) Membrane separation technology combined with ultrasonic-assisted filtration to extract proanthocyanidin which was from grape seed. This approach is simple, extremely efficient, low energy consumption, and better than the traditional approaches of heat extraction, enrichment process. If we use this approach into purification processing industry of agricultural production, agricultural resource would be fully used, and it has important significance to reduce production cost.

(2) An ultrafiltration equipment which vibrator equidistant installed on the membrane module shell has been designed to research the process of ultrafiltration. Experiments show that the ultrasonic field structure can effectively strengthen the ultrafiltration process and improve membrane flux.

(3) Due to the highly nonlinear fitting of BP neural network and the ability of genetic algorithm to global optimizing, BP neural network and genetic algorithm have been combined. Therefore, this model solves a complex problem whereas ultrasonic factors are difficult to be described by accurate model.

CONFLICT OF INTEREST

The authors confirm that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

This work was financially supported by project of the natural science foundation of Jiangsu Province; foundation number: BK20131250. The agricultural independent Iinnovation plan of Jiangsu Province; foundation number: CX(14)2092.