REVIEW ARTICLE

A Critical Review on Microbial Fuel Cells Technology: Perspectives on Wastewater Treatment

V. Venkatramanan1, Shachi Shah1, Ram Prasad2, *

Article Information

Identifiers and Pagination:

Year: 2021Volume: 15

Issue: Suppl-1, M7

First Page: 131

Last Page: 141

Publisher ID: TOBIOTJ-15-131

DOI: 10.2174/1874070702115010131

Article History:

Received Date: 15/11/2020Revision Received Date: 12/4/2021

Acceptance Date: 27/4/2021

Electronic publication date: 27/08/2021

Collection year: 2021

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Increasing demand for renewable energy in the backdrop of global change calls for waste valorization and circular economy strategies. Public health concerns and demand for clean energy provide impetus to the development of wastewater based MFC. Wastewater treatment and simultaneous generation of bioelectricity offer a myriad of environmental benefits. Nevertheless, it is pertinent to know the challenges with the microbial fuel cell (MFC) technology to upscale the wastewater based MFC. This paper attempts to critically analyse the processes, application, challenges and opportunities of wastewater based MFCs. A literature survey was conducted to find out the advances in the field of wastewater based MFCs and the focus was to decipher the challenges to the implementation of wastewater based MFCs. Recent developments in MFC technology have improved the power output and studies show that a diverse group of organic-rich wastewater can be treated with MFCs. The developments include improvements in MFC configuration, development of biocatalysts and biocathode, anodic biofilm formation, microbial community interactions, and progress in the organic and pollutant removal. Nevertheless, the MFC technology is replete with challenges about the organic removal rate, power density, electrode performance limiting factors, economic viability, high initial and maintenance cost and difficulty to maintain the exoelectrogens activity in a complex wastewater environment. Opportunities exist in scaling up of MFCs, integration with other wastewater treatment methods and measures to minimise the operating costs. MFCs have the potential to increase the resilience capacity of the sustainable wastewater treatment plant.

1. INTRODUCTION

Increasing demand for renewable energy in the backdrop of climate change realities, human-induced global change and environmental pollution calls for waste valorisation and circular economy [1]. Growing environmental and public health concerns demand sustainable wastewater treatment [2]. Increasing desire for clean water, resource and energy recovery, pollutant removal led to the development of sustainable green technologies. In this regard, the growth of biological fuel cells is a significant development in the renewable energy paradigm [3]. Nevertheless, the conceptual development of fuel cells started from the work of William Groves in 1839 [4]. Biological fuel cells are devices capable of generating electrical energy from chemical energy through the use of biocatalyst and electrochemical reactions. In such type of fuel cells, the organic-rich substrates are oxidized in the anode compartment through the action of microorganisms which releases the degradation products such as electrons, protons and carbon dioxide. The electrons released reach the anode and subsequently transported to the cathode. The hydrogen crosses the proton exchange membrane to reach the cathode compartment. The electrons are accepted by the electron acceptor such as oxygen in the cathode. The electron and proton reduced in the cathode compartment to form water or other products. MFCs are a promising green technology that has been found to be applied in wastewater treatment including nutrient removal and recovery, organic removal and pollutant removal [5, 6]. Several studies reported the application of MFC in wastewater treatment namely treatment of domestic wastewater [7, 8], cattle manure, brewery wastewater [9], and waste sludge [10, 11]. Application of MFC in the wastewater treatment provides multiple benefits namely bioelectricity generation offsets to a certain extent the wastewater treatment process; pollution reduction and removal [3]. Nevertheless, the MFC technology is replete with issues such as low power density, high initial capital investment, difficulty in scaling-up, electrode and MFC configuration, exoelectrogens activity in complex wastewater environment and electrode performance limiting factors [2, 6]. This paper provides critical insights about the MFC processes, application of MFCs in wastewater treatment, and challenges of MFC technology.

2. MICROBIAL FUEL CELL

2.1. Microbial Fuel Cell Processes

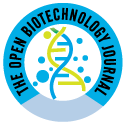

Microbial fuel cell technology is a promising green technology, with immense potential in waste management. MFCs are the devices which can convert biochemical energy into electrical energy through the action of microbes. The MFCs involve (a) microbes as biocatalyst, (b) enable electron transport either directly or through mediators (electron shuttles), and (c) electron acceptors. The MFCs are galvanic cells, wherein the electrochemical reaction possesses negative free reaction energy leading to a positive standard cell voltage [12]. Since it possesses negative free reaction energy, the reactions cause spontaneous electron release. Mostly MFCs use bacteria as a catalyst. Generally, the microbial consortia isolated from wastewater streams are selected for employing in MFCs. The cellular respiration products of exoelectrogens include carbon dioxide, protons and electrons. The MFCs traditionally are made of anode and cathode compartment, separated by a proton exchange membrane [7, 13]. Fig. (1) shows a typical two-chamber Microbial Fuel Cells.The anode electrode placed in the anode compartment with the analyte is maintained under anoxic condition. On the other hand, the cathode electrode and catholyte placed in the cathode compartment are maintained under aerobic conditions [14]. Proton exchange membranes ensure anaerobic anode chamber and aerobic cathode chamber. The electrons released as a result of oxidation of organic matter in the wastewater reaches the anode either in the presence or absence of mediators [15]. The electron transfer between microorganisms and electrode takes place in the following ways: (a) through redox-active proteins present on the outer cell membrane (c-type cytochromes), (b) through mediators or electron shuttles, and (c) direct transfer of electrons from microorganisms to electrodes through specialised locomotive organs like pili, fimbriae, etc. The MFCs that employ mediators for electron transport are called mediator-based-MFCs. The mediators such as thionine, humic acid, neutral red, methylene blue aid in the transfer of electrons from the bacteria to the anode. Sharma and Kundu [16] listed the following properties to identify an ideal mediator: (i) the mediator must exhibit reversible redox reaction and should have low formal potential; (ii) the mediator should be soluble in an aqueous solution. The mediators capture the electrons from the bacterial cells and transfer them to the anode. Nevertheless, mediatorless-MFC generates bioelectricity through the action of electrogenic bacteria on the organic matter. Exoelectrogens are a group of organisms capable of thriving on biodegradable substances [17]. The electrons from the anode through a power load or resistor reaches the cathode. The terminal electron acceptor, mostly the oxygen, in the cathode compartment accepts electrons to form hydroxyl ion. The protons produced in the anode compartment on account of organic matter degradation move across the proton exchange membrane to reach the cathode compartment. The proton exchange membrane can be Nafion, Ultrex or salt bridge. The MFC can be a single chamber or traditional two-chamber MFC based on the absence or presence of proton exchange membrane respectively. The processes occurring at the anode and cathode are explained below through the chemical equation.

|

Fig. (1). A typical two-chamber Microbial Fuel cells. Source: Yuan and He [18]. |

Oxidation-Reduction Reaction (ORR) taking place in MFCs is responsible for electricity generation. ORR involves electron release (substrate), transfer (electrodes) and acceptance (electron acceptor). ORR essentially aids in the removal of pollutants. In wastewater based MFCs, the electron donors are the substrates [wastewater] and the terminal electron acceptors are oxygen, nitrate, phosphate, Fe [III], etc. The terminal electron acceptors such as nitrate, phosphate, etc. are the pollutants.

2.2. Anodic Reactions

In the anode compartment, the oxidation of organic-rich wastewater releases carbon dioxide, electrons and protons. Use of microbes as an anodic catalyst to breakdown the organic matter provides opportunities to generate electricity. The bacteria used as anodic biocatalyst include Geobacter sulfureducens [19], Shewanella oneidensis [20], Saccharomyces cerevisiae [21], Rhodopseudomonas palustris [22], and Escherichia coli [23]. The biocatalyst used in MFCs was reviewed by Sharma and Kundu [16] and Guo et al. [6]. The composition of an anode, the surface area of an anode and biofilm-forming exoelectrogens influence the bioelectricity generation. The anode must have significant conductivity and a large surface area to increase electron transport. The anode is made of carbon plates, platinum rods or carbon nanotubes. The carbon nanotubes are reported to possess large surface area [24].

2.3. Cathodic Reactions

Conventionally, the microbial fuel cell is constructed with two chambers namely the anode and the cathode chamber, separated by a proton exchange membrane. While the anode chamber is known for electrochemically active microorganisms, the cathode chamber is devoid of microbial activity. Air cathodes with platinum catalyst and costly electron acceptors such as ferricyanide are unsustainable [12]. Cathode configuration is another factor that decides the efficient functioning of MFCs. Studies on cathode configuration aim to improve the bioelectricity generation and use of MFC for wastewater treatment plants and removal of pollutants [25]. Catalysts have been used on the surface of the cathode to reduce the “cathode activation overpotential” and increase the power output of MFC. The catalysts normally used are platinum-coated cathode, biocathode, biocatalysts, etc. The biocatalysts include but not limited to Leptothrix discophora, Geobacter sulfurreducens, Geobacter lovleyi, Nitrosomonas sp. and Actinobacillus succinogenes. To catalyse the reaction in the cathode chamber, biocathode was developed [16]. The use of biocathodes in MFC aids in altering the cathode chamber and using terminal electron acceptors such as nitrate, sulphate which are otherwise environmental pollutants. These pollutants are reduced in the cathode chamber. Biocathodes are basically of two types. The aerobic biocathode uses microbes and oxygen to oxidize the metals such as Mn [II] and Fe [II]. On the other hand, anaerobic biocathodes use nitrate, sulphate, iron, manganese, selenate, etc. as electron acceptors [26]. Use of microbes in both anode and cathode chamber decreases the internal resistance [27]. It must be noted that the power density in an MFC is dependent on the internal resistance of the system. Tran et al. [28] studied the efficiency of MFC in terms of organic removal and nitrification. Nitrifying biocathode increased maximum power density by 68% and the ammonium was converted to nitrate. Further, COD removal was nearly 98%.

2.4. Exoelectrogens

The MFCs use bacteria as the main catalyst. The self-replicating nature of bacteria ensures self-sustainability of MFC and efficient oxidation of organic substances in wastewater. Kim et al. [29] reported that the bacteria, Shewanella putrefaciens can transfer the electrons directly to electrode surface without external mediators [29]. Exoelectrogens are organisms used in MFC for bioelectricity generation [17]. These organisms are capable of transporting the electrons through electron transfer mechanisms such as oxidation-reduction active proteins, nanowires or mediators. The functioning of MFCs is dependent on the efficiency of exoelectrogens in transporting the electrons. It is reported that the microbial consortia or mixed culture possess better capabilities in wastewater treatment. Table 1 lists the exoelectrogens and the substrates used in the MFCs. The phylum Proteobacteria is predominant among the microbial communities that develop on the anode. Nevertheless, the bacterial community composition directly depends on the enrichment conditions [30]. The power generation or power density of MFCs is a function of the nature of substrates, electrode composition, exoelectrogens and the configuration of the reactor [31].

| Microorganisms |

Substrates/ Co-substrates |

Current density/power density |

References |

|---|---|---|---|

| Pure Culture | |||

| Rhodoferax ferrireducens | Glucose, xylose sucrose, maltose | 158 mW/m2 | [32] |

| Pseudomonas aeruginosa | Pyocyanin | 4310 mW/m2 | [33] |

| Saccharomycescerevisiae | Glucose | 16 mW/m2 | [24] |

| Pseudomonas sp. | Peptone | 979 mA/cm2 | [34] |

| Klebsiella pneumoniae strain L17 | Glucose | 34.77 mW/m2 | [35] |

| Shewanella oneidensis strain 14063 | Sodium pyruvate | >40 mW/m2 | [36] |

| Escherichia coli strain K-12 | Sucrose | 215 mW/m2 | [37] |

| Cellulose degrading bacteria | Cellulose | 188 mW/m2 | [38] |

| Mixed Culture | |||

| Thermophilic effluent from anaerobic digestion of brewery wastewater | Acetate | 1030 mA/cm2 | [39] |

| Gammaproteo and Shewanella affinis [KMM3586] | Cysteine | 36 mW/m2 | [38] |

| Desulfobulbus and Clostridium | Rice straw hydrolysate | 137.6 mA/cm2 | [40] |

| Fly ash leachate | Fermentation effluent | 85.07 mA/cm2 | [41] |

2.5. Materials for MFC

The MFCs require improved anode and cathode electrodes, separator and innovative MFC design. The aim is to reduce the capital and maintenance cost and also to improve the efficiency of MFCs. The anode configuration should consider the provision of favourable condition for microbes and facilitate biofilm growth. The requirements for anode electrodes are high porosity and specific surface area, resistance to fouling and corrosion [42]. The carbon-based materials are preferred as anode material. Plain graphite, carbon paper, graphite felt, carbon cloth, carbon nanotube are few examples of carbon-based anode materials. About cathode electrode, intensive efforts have been undertaken to look for an alternative to a platinum catalyst. Metal-organic compounds are preferred in place of a platinum catalyst. Biocathode is considered as an alternative to the abiotic cathode. Biocathode possesses immense potential in wastewater based MFCs, as they aid in pollutant removal. The requirement for proton exchange membrane is resistance to biofouling and corrosion and the ability to provide oxygen permeation.

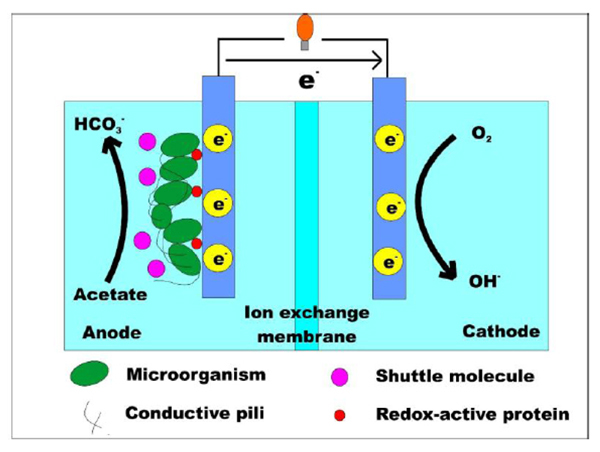

3. APPLICATION OF MFC IN WASTEWATER TREATMENT

Wastewater is a source of concern as it pollutes the surface and groundwater bodies [12]. Nevertheless, it is reported that the wastewater contains nearly 3 to 10 times the energy required to treat wastewater [43]. The energy in wastewater is present in the form of organic matter, nutrients and thermal energy. Though thermal energy constitutes the most, it cannot be harvested efficiently. On the other hand, the chemical energy locked either in the organic component or nutrients can be harvested [44]. Conventional wastewater treatment technologies require transformation, as they are unable to meet the growing demand and are cost- and energy-intensive. The wastewater treatment plants involve activated sludge treatment process. This process involves a huge cost (aeration process, sludge disposal). Nevertheless, it shows good results concerning the treatment of wastewater. As regards the anaerobic digestion process, technology is employed to treat high strength wastewater. It also provides valuable bioenergy [biogas]. In the anaerobic digestion process, the sludge is acted upon by the microbes and the carbon in the sludge is converted into methane. In this regard wastewater based MFCs provide a sustainable pathway in wastewater treatment (Fig. 2). MFCs are now established as a sustainable alternative to conventional wastewater treatment methods. MFCs do not involve issues of sludge management [45].

Wastewater based MFCs were conceptualized and studied by Habermann and Pommer [46], Min and Logan [8] and Cheng et al. [47]. Min and Logan [8] using flat plate MFC generated bioelectricity from domestic wastewater and organic-rich substrates. Their work highlighted the application and power generation capacity of MFC with diverse organic substrates. Secondly, it was observed that the MFCs can be used as a continuous flow reactor system [16]. Further, the power output from wastewater based MFCs decreased, when the electrode spacing is reduced [47]. The anodic bacterial activity reduced when the anode is brought closer to the cathode.

The anodic bacterial growth is significant for the performance of MFCs. Venkata Mohan et al. [48] studied the effect of anodic biofilm on the bioelectricity production in “single-chambered mediator less-MFC”. The study highlighted the usefulness of anodic biofilm in augmenting the “extracellular electron transfer” [48]. The power output of wastewater based MFCs is dependent on wastewater concentration [49]. As regards the scalability of MFCs, the small-sized MFC was reported to be superior to medium-scale and large-scale MFC [50].

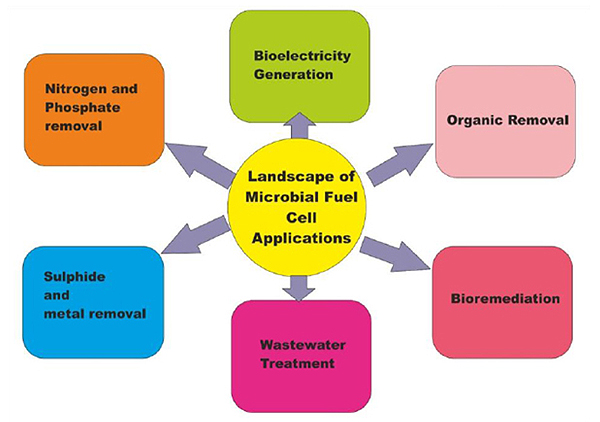

Sustainable wastewater treatment is the need of the hour. Sustainable wastewater treatment endeavours to minimise environmental pollution, to recover and reuse resource, and to generate energy [2]. MFC is a promising technology in sustainable wastewater treatment. Further, the benefits due to the adoption of MFCs include but not limited to energy benefits, economic and environmental benefits and generation of value-added products [2, 12]. Municipal and industrial wastewaters particularly food-processing industries, brewery industries are rich in organic carbon and considered as a source of energy. MFCs in wastewater treatment generate clean electrical energy and also consume less energy as compared to the conventional wastewater treatment methods [2]. Concerning pollutant removal, the decontamination potential of MFCs is significant. It is reported that the persistent contaminants, aqueous contaminants, nutrients [nitrogen and phosphorus], recalcitrant organic pollutants, sulphur compounds and metals are removed by the MFCs. Compared to the conventional wastewater treatment plants, MFCs offer environmental sustainability through low carbon footprint and low sludge production.

On account of unique features and multiple benefits (Fig. 3), MFCs are preferred to be integrated with wastewater treatment [6]. MFC integration with wastewater treatment plants enhances the robustness and stability of the system. For instance, the formation of biofilms through the action of microbial communities provides resilience to MFCs. The microbial communities in the biofilm provide resistance to the toxic contaminants and also withstand the fluctuations of temperature and pH. Further, the real-time monitoring of the MFCs augments the efficient functioning of MFCs. The operational lifetime of MFCs in wastewater treatment is nearly two years. The positives of MFCs can be exploited efficiently through the integration of MFCs with other wastewater treatment technologies. While the MFCs are more suitable to treat low-strength wastewaters, anaerobic digestion is preferred for treating high-strength wastewaters. Also, particulate rich wastewaters and brewery wastewaters are better treated using anaerobic digestion. In this regard, the anaerobic digestion-MFC integrated process is recommended to treat various types of wastewaters and provide opportunities for pollutant removal and energy recovery.

|

Fig. (2). Applications of Wastewater based MFC. |

|

Fig. (3). Advantages of MFC technology for treating wastewater. Source: Guo et al. [6]. |

3.1. Organic Removal

MFCs are capable of utilising organic compounds present in the wastewater such as agricultural wastewater, domestic wastewater and food/industrial wastewater. To understand the feasibility of using MFC for wastewater treatment, energy recovery mechanism and performance, technical feasibility, earlier studies on organic removal using MFC were conducted on synthetic wastewater. The synthetic wastewaters used in studies [12] were acetate [51-53], glucose [33, 52], sucrose and other organic compounds [12]. In the case of synthetic wastewaters, the organic removal percentage was significant. Gude [12] has reviewed wastewater based MFCs from the perspective of organic removal and energy recovery. MFCs are employed in the treatment of a wide variety of wastewater. The wastewater substrates employed by the MFCs include domestic wastewater [54, 55], agricultural wastewater [54], dairy wastewater [56, 54], distillery wastewater [57], food processing wastewater [58], etc. High carbohydrate-rich wastewater such as food processing wastewater, animal wastewater is ideal for bioelectricity generation through MFC. The algae-based MFC employ the natural syntrophic relationship existing between the bacteria and photosynthetic algae [12]. Algae treat organic-rich waste and nutrients with minimal energy use. The performance of MFC is dependent on the biofilm establishment and growth, substrate concentration and composition, efficiency of proton exchange membrane, electrode surface area, electrode potential, internal resistance, etc.

Exoelectrogens are used for generating electricity in the MFCs. About 35 pure cultures including Geobacter, Pseudomonas sp., Rhodoferax, Shewanella, Cupriavidus basilensis, Lactococcus lactis, and Propionibacterium freudenreichii, etc. have been reported as exoelectrogens in MFCs [59]. Mixed cultures are also suitable for bioelectricity generation. Mixed cultures used in MFCs for organic matter degradation are beneficial from the point of view of using substrates, adapting to varied environmental conditions, etc. In the MFCs fed with artificial wastewaters, the dominant phyla observed were Proteobacteria and Bacteroidetes. It was reported that Deltaproteobacteria species are responsible for the generation of electricity. Further, the bacterial organisms such as Desulfovibrio, Butyricicoccus, Petrimonas and Propionivibrio dominate the anodic biofilm [60] and provide twin benefits of bioelectricity generation and organic matter removal.

3.2. Removal of Nitrogen

Wastewaters are typically rich in nutrients such as nitrogen and phosphorus. These nutrients, if present, more than the self-regulating capacity of the system, result in eutrophication in water bodies. Nitrogen release into the environment is a cause of concern, as it leads to cascading negative influence on the aquatic ecosystem. Conventionally, the wastewater treatment process involving the nitrification (ammonia oxidation to nitrate) and denitrification (nitrate reduced to nitrogen gas) processes are preferred for the nitrogen removal [61]. ANAMMOX [Anaerobic ammonium oxidation] is considered better than the nitrification and denitrification process, as it is more energy-efficient. Anammox process involves the microbially mediated conversion of ammonium and nitrite to nitrogen [56]. Nevertheless, the conventional treatment methods are cost- and energy-intensive and also constrained with a generation of a huge amount of sludge [56]. In the MFC, the anaerobic microorganisms degrade the organic matter in the wastewater into carbon dioxide, proton and electron. The electrons so produced as a result of the oxidation process are transferred to the anode by the exoelectrogens. The electron reaches the cathode through an external circuit. The coupling of anodic oxidation and cathodic reduction results in the generation of electricity. The ammonium ion present in the wastewater (anodic compartment) is transported across the ion exchange membrane either actively (NH4) or passively (NH3) to the cathode compartment. The catholyte due to higher pH levels enables recovery of NH3 from NH4.

Microbial Fuel Cells (MFCs) have been considered as an option to treat wastewater because they can operate without aeration [62]. In this regard, a variety of MFCs were developed using air-cathode technology for treating wastewater. A flat panel air-cathode MFC (FA-MFC) developed by Park et al. [62] was used to treat domestic wastewater with a short Hydraulic Retention Time (HRT) of 2.5 h. The FA-MFCs after eight months of operation were able to remove 85% of Chemical Oxygen Demand (COD) and 94% of Total Nitrogen (TN). Organisms like Nitrosomonas, Nitratireductor and Acidovorax spp.contributed to nitrogen removal. In another study, in the MFCs fed with wastewaters rich in nitrogen concentration, Thauera was reported to degrade the organic compounds and augment the nitrogen removal [60].

Nitrogen and phosphate compounds can be efficiently removed in MFCs with biocathode [12]. These nutrients can be recovered as ammonia or magnesium ammonium phosphate (Struvite) [12]. By combining the denitrification MFC and nitrification bioreactors, studies demonstrate simultaneous bioelectricity generation and nutrient removal. The nitrogen by itself can affect bioelectricity generation through its negative effects on microbes (anode-respiring bacteria) and pH [12]. The nitrogen removal process in MFC is influenced by factors such as pH, dissolved oxygen concentration and C/N ratio. While high pH and dissolved oxygen inhibit the denitrification process, the neutral pH is preferred for the nitrification-denitrification process. Kelly and He [61] reviewed the nutrient removal processes in the MFC systems.

3.3. Phosphate Removal

The phosphorus removal and recovery are of utmost importance due to environmental regulations and growing demand for phosphorus resources [2]. Traditionally, the phosphorus is removed from the wastewaters using technologies involving chemical precipitation, biological processes, etc. Chemical precipitation through the addition of precipitates is construed as low-cost technique of phosphorus removal. In the case of Enhanced Biological Phosphorus Removal (EBPR), selectively enriched Polyphosphate Accumulating Organisms (PAOs) are used to accumulate phosphate in their cells and subsequently, it is removed as waste sludge [63]. The phosphate is removed from the wastewater in the form of struvite. Struvite recovery is achieved through adjusting pH (addition of chemicals such as sodium hydroxide, magnesium hydroxide, calcium hydroxide) or carbon dioxide stripping (through aeration process) or electrolysis [5, 12]. Fisher et al. [58] demonstrated the removal of phosphorus through wastewater based MFCs. In the cathode compartment, due to the reduction process, orthophosphate was released from iron phosphate. Subsequent addition of magnesium and ammonium coupled with pH adjustment resulted in the formation of struvite. Studies by Ichihashi and Hirooka [64], Palanisamy et al. [5] further established phosphate removal in MFCs. The recovery of struvite in MFCs is influenced by the availability of high-strength wastewater, optimum pH, availability of magnesium, struvite precipitation on electrode and membranes [12]. The formation of struvite also aids in the removal of nitrogen and phosphate [5]. The phosphate removal from the wastewater can be used as fertilizer [2, 5, 12]. Studies have been undertaken to integrate the MFCs with algal bioreactor so as to improve the phosphorus removal [2, 63]. The autotrophic organisms like algae consume phosphorus and other nutrients in the wastewater for synthesis of biomass. A removal efficiency of 92.0% for COD and 82.0% for phosphorus was observed in the integrated photo-bioelectrochemical system [63].

3.4. Sulphide Removal from Wastewater

Wastewaters from food processing industries, petrochemical industries, tanneries, paper and pulp industries, animal husbandry, acid mine drainage, etc. are rich in sulphates [65, 66]. Due to its negative effect on the environment and human health, the sulphide emission is a cause of concern. The problems arising due to sulphate-laden wastewaters include corrosion and odour issues. Conventional methods such as volatilization, precipitation, adsorption and oxidation aim to remove sulphide. Nevertheless, the cost and energy requirement is deterrent [5]. Further, the conventional biological treatment involves microbes mediated reduction of sulphate and subsequent oxidation of sulphide. Simultaneous reduction and oxidation environment provided by MFCs are useful for sulphide removal from the wastewaters. The sulphide removal in MFC is ensured through the action of sulphate-reducing and sulphide-oxidizing bacteria in the anode. Suitable anode potential is required for enhancing sulphide removal. The sulphate-reducing bacteria such as Desulfovibrio sp. reduce the sulphate to sulphide. The sulphide is subsequently oxidised to sulphur by the action of sulphide-oxidising bacteria like Thiobacter sp [66]. The Sulphate-reducing bacteria namely Desulfobulbus propionicus, Desulfobulbus elongates, Desulfovibrio desulfuricans, Desulfuromonas acetoxidans and Desulfobulbus mediterraneus are reported to be exo-electrogenic with specific function in sulphate reduction [67]. Smita et al. [66] reported that the MFCs using microbial consortium consisting of Clostridium, Desulfovibrio and Tetrathiobacter species are effective in removing sulphide from wastewaters. The microbial consortium requires slightly alkaline environment for electricity generation. Blazquez et al. [65] highlighted the research priorities for sulphate rich wastewaters fed MFCs: (a) the development and optimization of processes to optimize the reaction rates; (b) improvement of operational cost and (c) recovery of products like elemental sulphur.

3.5. Metal Removal

The metals in the wastewater demand advanced treatment methods for its removal. Nevertheless, the metals with the high redox potential can be employed as an electron acceptor in MFCs. MFCs have emerged as a new technology to remove the heavy metals such as nickel, chromium, zinc, and copper [68]. The MFC-mediated wastewater treatment can generate electricity and aid in the removal of metals. In the MFCs, the electrons produced from the microbial metabolism are used to reduce the metals in the wastewaters. Microbial mediated dissimilatory metal reduction enables microbes to conserve energy through the oxidation of substrates and reducing metals. Microbes receive energy for its growth through metal reduction [12]. The metals so used as electron acceptor reduce and precipitate. Wang and Ren [69] reviewed the metal removal capabilities of MFC. Huang et al. [70] reported the removal of cobalt metal as cobalt hydroxide in biocathode based MFCs. Studies were also performed on wastewater fed MFCs from the perspective of copper removal. Wu et al. [71] reported the predominant role of Geobacter (anodic biofilm) in organic matter degradation and electricity generation. The exoelectrogenic bacteria Geobacter, which forms thick and highly conductive anodic biofilms, produce electrons by oxidising organic matter and transfer the electrons to the anode by pili. Acinetobacter, Ignavibacterium, and Paludibacter were also found in the anodic biofilm. Organisms like Nitratireductor, Ochrobactrum, Serratia and Azoarcus present in the cathodic biofilms played key role in copper removal from the wastewaters. Nevertheless, the acclimatization of microbial communities is advantageous for metal removal from wastewaters.

4. CHALLENGES AND OPPORTUNITIES

Wastewater based MFCs are a significant component of sustainable wastewater treatment. Wastewater based MFCs in addition to providing environmental benefits, generate bioelectricity. In the previous sections, the MFC processes, applications of MFC in wastewater treatment were discussed. In this section, the challenges to wastewater based MFC technology and opportunities that exist in wastewater based MFC are discussed. The challenges to MFC include (a) low power output, the cost factor and low rates of pollutant removal [12]; (b) Maintaining the electrochemically active microorganisms in a complex wastewater environment [2]; (c) Fluctuations in the operating conditions of MFC and deterioration in the functioning of electrodes limit the performance of MFCs; (d) deterioration of electrode performance due to “fouling”, “corrosion” and “clogging of electrodes” [2]. So far, several attempts have been carried out to address these challenges but pragmatic measures are limited. Nevertheless, the research should focus on removing the barriers to the implementation of wastewater MFCs. The future perspectives lie on scaling up MFC technology, increasing power output and integrating MFC with other wastewater treatment methods.

4.1. Organic Removal Rates

Studies show that the organic removal rates for MFC range between 0.0053 and 5.57g COD/l/day [72]. However, for the MFC to be economically viable, the organic removal rate should be 5-10 g COD/l/day [73]. There is a gap between actual and expected organic removal rates. Further, the studies on wastewater based MFCs are vulnerable to uncertainty, as the studies are mostly based on batch-fed and small-scale operating conditions. Gude [12] observed that (a) anaerobic sludge as feedstock is better than the activated sludge, (b) biofouling of cathode causes low performance of MFC. There is a need for further research to gauge the potential of wastewater based MFCs.

4.2. Power Density

The MFCs recover a significant amount of energy from organic matter decomposition in wastewater through bioelectricity generation. Nevertheless, the MFC performance and electron transfer mechanism are a cause of concern demanding intensive research [12]. Bioelectricity generation by a large scale MFC is much lesser in the order of W/m3, which is much less than the target of 1 KW/m3 [2]. Janicek et al. [72] reported the power density of an MFCs between 0.2 to 200 W/m3. The power density of MFC was found to be lower. Studies on the reasons for low power density reveal the causes such as the composition of wastewater, electrode materials and proton exchange membrane materials and low conductivity and pH characteristics of wastewater. Further, the MFC performance is dependent on pH balance and low cathode reduction activities. The Oxygen Reduction Reaction [ORR] in the cathode compartment is sluggish. The oxygen reduction reaction is one of the challenges for the development of MFCs. In this regard, the challenge is to develop a sustainable catalyst for the ORR. The catalysts presently explored include “enzymatic, chemical and microbial catalysts”. Presently, a platinum catalyst is used. However, nearly 50% of the total capital cost (of MFC) is accounted for platinum cost [74]. The challenge of low power density can be overcome by addressing electrode configuration, separator materials, electrode circuit architecture, biofilm growth and development [12].

There are a lot of opportunities to recover energy from the wastewater, as the energy content of wastewater is high. For instance, the energy content of municipal wastewater is 1.2 KWh/m3. Large scale application of wastewater based MFC technology requires the development of bioanode and biocathode [75]. Extensive research has been conducted on the bioanode. Nevertheless, recent research interest on biocathode due to its effect on MFC performance and wastewater treatment calls for appreciation. Biocathode is a recent improvement in MFC technology. Microorganisms on the cathode surface can take up an electron to reduce oxygen. Biocathodes help in reducing the cost of MFC by replacing costly platinum catalyst and also helpful for wastewater treatment. The catalytic efficiency improved greatly because of biocathode (microbial community interaction) [16, 74].

4.3. High Initial and Maintenance Cost

High initial capital investment and maintenance cost challenge the economic viability of MFCs. Wastewater based MFC capital cost is nearly 30 times more than the conventional activated sludge treatment [5]. The higher capital cost is due to the expensive electrode materials and separator materials [12]. The abiotic electrode catalyst (platinum) and electrode binders (Nafion) that are currently used in the MFCs are cost-prohibitive. To upscale the MFC technology and implement on an industrial scale, there is a need for the development of bioelectrodes. The bioelectrodes should be cost-effective and possess the potential to augment power density and waste treatment capabilities. Further, the returns obtained from energy production are much lesser. Nevertheless, the environmental benefits (public health and pollutant removal) cannot be overestimated. The cost involved in wastewater based MFCs can be reduced by adopting a decentralised wastewater treatment mode. Decentralised wastewater based MFCs reduces the cost of transportation of wastewater and energy consumption.

4.4. MFC Integration with other Wastewater Treatment Methods

Standalone MFC performance is lower than the hybrid or integrated MFC system [76]. Further, the integration of MFCs with the wastewater treatment methods provides opportunities in waste remediation. Studies report about the integration of MFC with wastewater treatment methods such as constructed wetlands, aerated lagoons, anaerobic digesters and sludge treatment plants [12, 76, 77]. MFC system can be integrated at various levels (centralised system/decentralised system/ community level). The integrated MFC system will improve the energy and resource utilisation efficiencies. Nevertheless, MFC integration with other wastewater treatment methods may present issues about operation and maintenance [12].

5. FUTURE PERSPECTIVES

Amongst the different wastewater treatment techniques, such as aerobic treatment, anaerobic digestion and chemical treatment, MFC is construed as a reliable technology with triple benefits of bioelectricity generation, wastewater treatment and pollutant removal [6]. As compared to the conventional wastewater treatment techniques, MFC technology has characteristic advantages such as lesser environmental footprints, energy benefits, metal removal, etc [6]. Nevertheless, the MFC operation and performance are challenged by high cost, shorter life span, membrane fouling and deterioration, and stability of biocatalysts. Nevertheless, the issues related to scaling up the MFC technology need to be addressed. The factors that influence scale-up of MFC include power generation, treatment efficiency, substrate composition, MFC configuration and design [3, 72]. The research on MFC should address these pertinent issues related to scaling up of MFC technology. Tremendous advances have been made in the performance of standalone MFCs. Nevertheless, further improvement in the performance is harder due to inherent factors and limitations on account of wastewater characteristics. Zhang et al. [76] reviewed the superior performance of MFC hybrid system for wastewater treatment. For instance, integration of MFCs with sludge treatment greatly improves the MFC performance and sludge degradation efficiencies [77]. In this regard, future research should focus on the development of hybrid MFC system, environmental impact analysis and life cycle assessment and measures to minimise the operating costs. The performance of MFC can be improved by increasing microbe-electrode interactions. Research to decipher the “molecular mechanism of microbe-electrode interaction”, biofilm formation and composition, biocatalyst can provide an impetus for increasing performance and economic viability of wastewater based MFCs [5, 6].

CONCLUSION

Increasing demand for clean water, resource and energy recovery, pollutant removal led to the development of sustainable green technologies. In this regard, the growth of biological fuel cells is a significant development in the renewable energy paradigm. Biological fuel cells are devices capable of generating electrical energy from chemical energy through the use of biocatalyst and electrochemical reactions. MFCs are a promising green technology that has been found to be applied in wastewater treatment including nutrient removal and recovery, organic removal and pollutant removal. Nevertheless, the MFC technology is replete with issues such as low power density, high initial capital investment, difficulty in scaling-up, electrode and MFC configuration, exoelectrogens activity in complex wastewater environment and electrode performance limiting factors. This paper provided critical insights about the MFC processes, application of MFCs in wastewater treatment, and challenges of MFC technology. The following perspectives should be considered to improve the performance of wastewater based MFCs.

- Issues related to scaling up the MFC technology need to be addressed. The factors that influence scale-up of MFC include power generation, treatment efficiency, substrate composition, MFC configuration and design.

- Studies on the electron transfer mechanisms, biocatalytic rate-constants and cell resistances will improve the MFC configuration.

- Future research should focus on the development of hybrid MFC system, environmental impact analysis and life cycle assessment and measures to minimise the operating costs.

- The integrated MFC-wastewater treatment system provides economic viability, environmental sustainability, and enhances the robustness and stability of the system.

- Research to decipher the “molecular mechanism of microbe-electrode interaction”, biofilm formation and composition, biocatalyst can provide an impetus for increasing performance and economic viability of wastewater based MFCs.

The future of wastewater based MFCs is filled with opportunities and challenges. The latter can be addressed through intensive research on barriers to MFC adoption, scaling up the MFC technology, power density and pollutant removal.

CONSENT FOR PUBLICATION

Not applicable.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.

REFERENCES

| [1] | Venkatramanan V, Shah S, Prasad R. Sustainable bioeconomy : Pathways to sustainable development goals 2021. |

| [2] | Li WW, Yu HQ, He Z. Towards sustainable wastewater treatment by using microbial fuel cells-centered technologies. Energy Environ Sci 2014; 7(3): 911-24. |

| [3] | Shah S, Venkatramanan V, Prasad R. Microbial fuel cell: Sustainable green technology for bioelectricity generation and wastewater treatment. Sustainable Green Technologies for Environmental Management 2019; 199-218. |

| [4] | Andújar JM, Segura F. Fuel cells: History and updating. A walk along two centuries. Renew Sustain Energy Rev 2009; 13(9): 2309-22. |

| [5] | Palanisamy G, Jung HY, Sadhasivam T, Kurkuri MD, Kim SC, Roh SH. A comprehensive review on microbial fuel cell technologies: Processes, utilization, and advanced developments in electrodes and membranes. J Clean Prod 2019; 221: 598-621. |

| [6] | Guo Y, Wang J, Shinde S, Wang X, Li Y, Dai Y, et al. Simultaneous wastewater treatment and energy harvesting in microbial fuel cells: An update on the biocatalysts. RSC Advances 2020; 10(43): 25874-87. |

| [7] | Logan BE, Hamelers B, Rozendal R, et al. Microbial fuel cells: methodology and technology. Environ Sci Technol 2006; 40(17): 5181-92. |

| [8] | Min B, Logan BE. Continuous electricity generation from domestic wastewater and organic substrates in a flat plate microbial fuel cell. Environ Sci Technol 2004; 38(21): 5809-14.https://pubs.acs.org/doi/10.1021/es0491026 |

| [9] | Feng C, Li J, Qin D, et al. Characterization of exoelectrogenic bacteria enterobacter strains isolated from a microbial fuel cell exposed to copper shock load. PLoS One 2014; 9(11)e113379 |

| [10] | Jiang D, Curtis M, Troop E, Scheible K, McGrath J, Hu B, et al. A pilot-scale study on utilizing multi-anode/cathode microbial fuel cells (MAC MFCs) to enhance the power production in wastewater treatment. Int J Hydrogen Energy 2011; 36(1): 876-84. |

| [11] | Wang Y, Zhang H, Li B, Feng Y. Integrating sludge microbial fuel cell with inclined plate settling and membrane filtration for electricity generation, efficient sludge reduction and high wastewater quality. Chem Eng J 2018; 331: 152-60. |

| [12] | Gude VG. Wastewater treatment in microbial fuel cells - An overview. J Clean Prod 2016; 122: 287-307. |

| [13] | Ishii S, Suzuki S, Norden-Krichmar TM, et al. Identifying the microbial communities and operational conditions for optimized wastewater treatment in microbial fuel cells. Water Res 2013; 47(19): 7120-30. [Internet]. |

| [14] | Nastro RA. Microbial fuel cells in waste treatment: Recent advances. Int J Perform Eng 2014; 10(4): 367-76. |

| [15] | Kim HJ, Park HS, Hyun MS, Chang IS, Kim M, Kim BH. A mediator-less microbial fuel cell using a metal reducing bacterium, Shewanella putrefaciens. Enzyme Microb Technol 2002; 30(2): 145-52. |

| [16] | Sharma V, Kundu PP. Biocatalysts in microbial fuel cells. Enzyme Microb Technol 2010; 47(5): 179-88. |

| [17] | Logan BE. Exoelectrogenic bacteria that power microbial fuel cells. Nat Rev Microbiol 2009; 7(5): 375-81. |

| [18] | Yuan H, He Z. Graphene-modified electrodes for enhancing the performance of microbial fuel cells. Nanoscale 2015; 7(16): 7022-9. |

| [19] | Reguera G, Nevin KP, Nicoll JS, Covalla SF, Woodard TL, Lovley DR. Biofilm and nanowire production leads to increased current in Geobacter sulfurreducens fuel cells. Appl Environ Microbiol 2006; 72(11): 7345-8. |

| [20] | Biffinger J, Ribbens M, Ringeisen B, Pietron J, Finkel S, Nealson K. Characterization of electrochemically active bacteria utilizing a high-throughput voltage-based screening assay. Biotechnol Bioeng 2009; 102(2): 436-44. |

| [21] | Raghavulu SV, Goud RK, Sarma PN, Mohan SV. Saccharomyces cerevisiae as anodic biocatalyst for power generation in biofuel cell: influence of redox condition and substrate load. Bioresour Technol 2011; 102(3): 2751-7. |

| [22] | Xing D, Zuo Y, Cheng S, Regan JM, Logan BE. Electricity generation by Rhodopseudomonas palustris DX-1. Environ Sci Technol 2008; 42(11): 4146-51. |

| [23] | Qiao Y, Li CM, Bao SJ, Lu Z, Hong Y. Direct electrochemistry and electrocatalytic mechanism of evolved Escherichia coli cells in microbial fuel cells. Chem Commun (Camb) 2008; (11): 1290-2. |

| [24] | Rahimnejad M, Adhami A, Darvari S, Zirepour A, Oh SE. Microbial fuel cell as new technology for bioelectricity generation: A review. Alex Eng J 2015; 54(3): 745-56. |

| [25] | Ucar D, Zhang Y, Angelidaki I. An overview of electron acceptors in microbial fuel cells. Front Microbiol 2017; 8(APR): 643. |

| [26] | Clauwaert P, Rabaey K, Aelterman P, et al. Biological denitrification in microbial fuel cells. Environ Sci Technol 2007; 41(9): 3354-60. |

| [27] | Chen GW, Choi SJ, Lee TH, Lee GY, Cha JH, Kim CW. Application of biocathode in microbial fuel cells: cell performance and microbial community. Appl Microbiol Biotechnol 2008; 79(3): 379-88. |

| [28] | Tran HT, Kim DH, Oh SJ, et al. Nitrifying biocathode enables effective electricity generation and sustainable wastewater treatment with microbial fuel cell. Water Sci Technol 2009; 59(9): 1803-8. |

| [29] | Kim BH, Kim HJ, Hyun MS, Park DH. Direct electrode reaction of Fe[III]-reducing bacterium, Shewanella putrefaciens. J Microbiol Biotechnol 1999; 9(2): 127-31. |

| [30] | Pant D, Van Bogaert G, Diels L, Vanbroekhoven K. A comparative assessment of bioelectrochemical systems and enzymatic fuel cells.Microbial biotechnology: Energy and environment 2012; 39-57. |

| [31] | Kim J-Y, Han S-B, Oh S-E, Park K-W. A Non-Pt Catalyst for Improved Oxygen Reduction Reaction in Microbial Fuel Cells. J Korean Electrochem Soc 2011; 14(2): 71-6. |

| [32] | Liu ZD, Lian J, Du ZW, Li HR. [Construction of sugar-based microbial fuel cells by dissimilatory metal reduction bacteria]. Sheng Wu Gong Cheng Xue Bao 2006; 22(1): 131-7. |

| [33] | Rabaey K, Lissens G, Siciliano SD, Verstraete W. A microbial fuel cell capable of converting glucose to electricity at high rate and efficiency. Biotechnol Lett 2003; 25(18): 1531-5. |

| [34] | Daniel DK, Das Mankidy B, Ambarish K, Manogari R. Construction and operation of a microbial fuel cell for electricity generation from wastewater. Int J Hydrogen Energy 2009; 34(17): 7555-60. |

| [35] | Liu Z, Liu J, Zhang S, Su Z. Study of operational performance and electrical response on mediator-less microbial fuel cells fed with carbon- and protein-rich substrates. Biochem Eng J 2009; 45(3): 185-91. |

| [36] | Fernando E, Keshavarz T, Kyazze G. Enhanced bio-decolourisation of acid orange 7 by Shewanella oneidensis through co-metabolism in a microbial fuel cell. Int Biodeterior Biodegradation 2012; 72: 1-9. |

| [37] | Zheng X, Nirmalakhandan N. Cattle wastes as substrates for bioelectricity production via microbial fuel cells. Biotechnol Lett 2010; 32(12): 1809-14. |

| [38] | Zhou M, Wang H, Hassett DJ, Gu T. Recent advances in microbial fuel cells [MFCs] and microbial electrolysis cells (MECs) for wastewater treatment, bioenergy and bioproducts. J Chem Technol Biotechnol 2013; 88(4): 508-18. |

| [39] | Jong BC, Kim BH, Chang IS, Liew PWY, Choo YF, Kang GS. Enrichment, performance, and microbial diversity of a thermophilic mediatorless microbial fuel cell. Environ Sci Technol 2006; 40(20): 6449-54. |

| [40] | Cui Y, Rashid N, Hu N, Rehman MSU, Han JI. Electricity generation and microalgae cultivation in microbial fuel cell using microalgae-enriched anode and bio-cathode. Energy Convers Manage 2014; 79: 674-80. |

| [41] | Varanasi JL, Roy S, Pandit S, Das D. Improvement of energy recovery from cellobiose by thermophillic dark fermentative hydrogen production followed by microbial fuel cell. Int J Hydrogen Energy 2015; 40(26): 8311-21. |

| [42] | Santoro C, Arbizzani C, Erable B, Ieropoulos I. Microbial fuel cells: From fundamentals to applications. A review. J Power Sources 2017; 356: 225-44. |

| [43] | Gude VG. Energy and water autarky of wastewater treatment and power generation systems. Renew Sustain Energy Rev 2015; 45: 52-68. |

| [44] | Gude VG, Kokabian B, Gadhamshetty V. Beneficial bioelectrochemical systems for energy, water, and biomass production. J Microb Biochem Technol 2013; S6: 005. |

| [45] | Logan BE, Rabaey K. Conversion of wastes into bioelectricity and chemicals by using microbial electrochemical technologies. Science 2012; 337(6095): 686-90. |

| [46] | Habermann W, Pommer EH. Biological fuel cells with sulphide storage capacity. Appl Microbiol Biotechnol 1991; 35(1): 128-33. |

| [47] | Cheng S, Liu H, Logan BE. Increased power generation in a continuous flow MFC with advective flow through the porous anode and reduced electrode spacing. Environ Sci Technol 2006; 40(7): 2426-32. |

| [48] | Venkata Mohan S, Veer Raghavulu S, Sarma PN. Influence of anodic biofilm growth on bioelectricity production in single chambered mediatorless microbial fuel cell using mixed anaerobic consortia. Biosens Bioelectron 2008; 24(1): 41-7. |

| [49] | Min B, Angelidaki I. Innovative microbial fuel cell for electricity production from anaerobic reactors. J Power Sources 2008; 180(1): 641-7. |

| [50] | Ieropoulos I, Greenman J, Melhuish C. Microbial fuel cells based on carbon veil electrodes: Stack configuration and scalability. Int J Energy Res 2008; 32: 1228-40. |

| [51] | Biffinger JC, Byrd JN, Dudley BL, Ringeisen BR. Oxygen exposure promotes fuel diversity for Shewanella oneidensis microbial fuel cells. Biosens Bioelectron 2008; 23(6): 820-6. |

| [52] | Chae KJ, Choi MJ, Lee JW, Kim KY, Kim IS. Effect of different substrates on the performance, bacterial diversity, and bacterial viability in microbial fuel cells. Bioresour Technol 2009; 100(14): 3518-25. |

| [53] | Liu H, Cheng S, Logan BE. Power generation in fed-batch microbial fuel cells as a function of ionic strength, temperature, and reactor configuration. Environ Sci Technol 2005; 39(14): 5488-93. |

| [54] | Nimje VR, Chen CY, Chen HR, et al. Comparative bioelectricity production from various wastewaters in microbial fuel cells using mixed cultures and a pure strain of Shewanella oneidensis. Bioresour Technol 2012; 104: 315-23. |

| [55] | Wang YK, Sheng GP, Li WW, et al. Development of a novel anaerobic membrane bio-electrochemical reactor for wastewater treatment and energy recovery. Environ Sci Technol 2011; 45: 9256-61. |

| [56] | Rodríguez Arredondo M, Kuntke P, Jeremiasse AW, Sleutels THJA, Buisman CJN, Ter Heijne A. Bioelectrochemical systems for nitrogen removal and recovery from wastewater. Environ Sci Water Res Technol 2015; 1(1): 22-33. |

| [57] | Samsudeen N, Radhakrishnan TK, Matheswaran M. Bioelectricity production from microbial fuel cell using mixed bacterial culture isolated from distillery wastewater. Bioresour Technol 2015; 195: 242-7. |

| [58] | Fischer F, Bastian C, Happe M, Mabillard E, Schmidt N. Microbial fuel cell enables phosphate recovery from digested sewage sludge as struvite. Bioresour Technol 2011; 102(10): 5824-30. |

| [59] | Kumar S, Kumar V, Malyan S, et al. Microbial fuel cells (MFCs) for bioelectrochemical treatment of different wastewater streams. Fuel 2019; 254115526 |

| [60] | Almatouq A, Babatunde A, Khajah M, Webster G, Alfodari M. Microbial community structure of anode electrodes in microbial fuel cells and microbial electrolysis cells. J Water Process Eng 2020; 34101140 |

| [61] | Kelly PT, He Z. Nutrients removal and recovery in bioelectrochemical systems: a review. Bioresour Technol 2014; 153: 351-60. |

| [62] | Park Y, Park S, Nguyen V, et al. Complete nitrogen removal by simultaneous nitrification and denitrification in flat-panel air-cathode microbial fuel cells treating domestic wastewater. Chem Eng J 2017; 316: 673-9. |

| [63] | Zhao N, Yan Q, He Z. Nutrients removal and recovery in bioelectrochemical systems.Microbial Electrochemical Technologies 2020; 155-70. |

| [64] | Ichihashi O, Hirooka K. Removal and recovery of phosphorus as struvite from swine wastewater using microbial fuel cell. Bioresour Technol 2012; 114: 303-7. |

| [65] | Blázquez E, Guisasola A, Gabriel D, Baeza J. Application of bioelectrochemical systems for the treatment of wastewaters with sulfur species 2019; 641-63. |

| [66] | Kumar SS, Kumar V, Gnaneswar Gude V, Malyan SK, Pugazhendhi A. Alkalinity and salinity favor bioelectricity generation potential of Clostridium, Tetrathiobacter and desulfovibrio consortium in Microbial Fuel Cells (MFC) treating sulfate-laden wastewater. Bioresour Technol 2020; 306123110 |

| [67] | Hemalatha M, Shanthi Sravan J, Venkata Mohan S. Self-induced bioelectro-potential influence on sulfate removal and desalination in microbial fuel cell. Bioresour Technol 2020; 309123326 |

| [68] | Yu Z, Han H, Feng P, et al. Recent advances in the recovery of metals from waste through biological processes. Bioresour Technol 2020; 297122416 |

| [69] | Wang H, Ren ZJ. Bioelectrochemical metal recovery from wastewater: a review. Water Res 2014; 66: 219-32. |

| [70] | Huang L, Liu Y, Yu L, Quan X, Chen G. A new clean approach for production of cobalt dihydroxide from aqueous Co[II] using oxygen-reducing biocathode microbial fuel cells. J Clean Prod 2015; 86: 441-6. |

| [71] | Wu Y, Wang L, Jin M, Zhang K. Simultaneous copper removal and electricity production and microbial community in microbial fuel cells with different cathode catalysts. Bioresour Technol 2020; 305123166 |

| [72] | Janicek A, Fan Y, Liu H. Design of microbial fuel cells for practical application: A review and analysis of scale-up studies. Biofuels 2014; 5(1): 79-92. |

| [73] | Clauwaert P, Aelterman P, Pham TH, et al. Minimizing losses in bio-electrochemical systems: the road to applications. Appl Microbiol Biotechnol 2008; 79(6): 901-13. |

| [74] | Yuan H, Hou Y, Abu-Reesh IM, Chen J, He Z. Oxygen reduction reaction catalysts used in microbial fuel cells for energy-efficient wastewater treatment: A review. Mater Horiz 2016; 3(5): 382-401. |

| [75] | Breheny M, Bowman K, Farahmand N, Gomaa O, Keshavarz T, Kyazze G. Biocatalytic electrode improvement strategies in microbial fuel cell systems. J Chem Technol Biotechnol 2019; 94(7): 2081-91. |

| [76] | Zhang Y, Liu M, Zhou M, Yang H, Liang L, Gu T. Microbial fuel cell hybrid systems for wastewater treatment and bioenergy production: Synergistic effects, mechanisms and challenges. Renew Sustain Energy Rev 2019; 103: 13-29. |

| [77] | Wang Z, Mei X, Ma J, Wu Z. Recent Advances in Microbial Fuel Cells Integrated with Sludge Treatment. Chem Eng Technol 2012; 35(10): 1733-43. |