All published articles of this journal are available on ScienceDirect.

Optimization of Anaerobic Digestion Processes of Organic Waste in Chiapas, Mexico, for Biogas Production

Abstract

Introduction

The production of biogas by the anaerobic decomposition of biomass guarantees an efficient and safe reduction of environmental pollution resulting from treating organic wastes, positioning it as a promising technology for the future.

The anaerobic digestion process carried out in this research project utilized pumpkin peel, tamarind peel, and corn cob leaves as substrates. Cow, sheep, and poultry fecal wastes were also analyzed as microbial inocula for biogas production. This research focused on evaluating the physical, chemical, and bromatological parameters of the aforementioned organic waste to determine the optimal parameters that define the stages of biogas production. This study is proposed because Mexico is the main generator of this waste, and lacks studies on its proper management.

Methods

The anaerobic digestion experiments were carried out in batch biodigesters with a capacity of 1.8 L at 36 ± 2 °C for a retention time of 30 days, using the methods of the Mexican Standards for Environmental Protection for the determination of humidity, ash, pH, Total Volatile Solids (TVS), Total Solids (TS), chemical oxygen demand, carbon, and nitrogen.

Results

Among the obtained results, the carbon/nitrogen ratio of the tamarind husk and corn cob leaves residues indicated a positive effect on biogas production in treatments mixtures 1 and 8, with values of 21.87 and 24.34, respectively, considered as values within the optimal range of 20:1 to 30:1, these values constitute the ideal availability of energy and nitrogen for cell replication of biogas producing methanogenic bacteria. These treatments were influenced by the Specific Methanogenic Activity (SMA) of the cattle manure inoculum, which had an organic matter biodegradability value of 0.58 grams of Chemical Oxygen Demand de Methane entre grams Total Volatile Solids for a day (COD-CH4/g TVS/day). This value supports the efficient assimilation of the carbon/nitrogen ratio based on the mentioned values. On the other hand, determining the TVS/TS ratio yielded percentages of 60%, 92%, and 95% in pumpkin peel, tamarind husk, and corn cob husks, respectively.

Discussion

Comparing the results with other studies, the optimal TVS/TS ratio should be greater than 50%; therefore, the results indicate that the substrates contain sufficient assimilable organic matter for anaerobic microorganisms and could produce biogas. Similarly, many scientific studies indicate that calculating the Specific Methanogenic Activity can not only determine the degree of biodegradability of substrates but also estimate possible pH changes in the medium, in addition to determining the maximum load of organic matter applied to any other type of anaerobic inoculum outside of this research work.

Conclusion

Under these conditions, the treatments obtained a cumulative biogas yield of 3645 and 4250 milliliters of methane, respectively. This research contributes to improving the quality of biogas through the management of standardized waste.

1. INTRODUCTION

Globally, the energy sector is dependent on the intensive use of fossil fuels such as oil, coal, and gas. These fuels have been the source of economic growth in Mexico and several countries. However, the massive use of fossil fuels has negative consequences, such as Carbon Dioxide (CO2) and Greenhouse Gas (GHG) emissions, which are the causes of ecological problems and climate change at a global level [1, 2]. According to data from the Commission for Environmental Cooperation (CCA), approximately 327.3 million tons per capita of organic waste from agro-industrial activities are generated annually in Mexico, of which only 7% is utilized through anaerobic digestion and industrial composting technology [3]. However, despite the fact that Mexico has the General Law for the Prevention and Comprehensive Management of Waste (LGPGIR) and the Mexican Official Standard NOM-083-SEMARNAT-2003, which sets the environmental protection specifications for the selection of the site, design, construction, operation, closure, and post-closure of the final disposal of urban solid waste. Efficient and accessible separation technologies are lacking, and the infrastructure is limited for large-scale waste management. Consequently, monitoring and quality control technologies in organic waste treatment processes are deficient and hinder the production of standardized and reliable final products. Therefore, the generation of these residues is also considered one of the major environmental impacts, primarily due to the poor disposal of solid waste that gives rise to air pollution (e.g., unpleasant odor), water contamination (underground and surface) causing the decrease of oxygen (O2), deaths of aquatic species and the production of GHG. In the soil, the decomposition of organic matter produces bad odor and leachate, which can be a potential risk to the environment and human health [4, 5]. To avoid mismanagement, accumulation, and contamination of the environment by the generation of organic waste, it is necessary to employ technologies such as anaerobic digestion, a biological process capable of degrading organic matter in the absence of O2 and through the elimination or organic purification caused by multiple microorganisms that transform waste into renewable energy in the form of methane-rich biogas [6, 7].

Anaerobic digestion is a renewable energy-based technology and model for practical use to treat and valorize various organic waste streams through four stages: the first is hydrolysis, where organic matter is changed in simple compounds (monomers), followed by acidogenesis, which produces organic acids through the fermentation of organic molecules and the third is acetogenesis, characterized by the formation of acetates, propionates and butyrates; finally, methanogenesis where Methane Gas (CH4) is produced [6, 8, 9]. However, due to the organic waste combinations, this technology can be limited in any of the stages mentioned above. Key challenges during biogas production include the presence of highly biodegradable organic matter, acidic pH, lack of alkalinity, and high concentrations of nitrogen (N) and Long-Chain Fatty Acids (LCFA) [10, 11], all of which can inhibit microbial activity and disrupt the digestion process. The stages of biogas production are optimized based on optimal conditions of temperature, pH, Total Volatile Solids/Total Solids Ratio (TVS/TS), and the Carbon/Nitrogen ratio (C/N). These parameters ensure the stability of the process, maximize CH4 content, and enhance the energy content of the biogas [6].

Although the management of organic waste through the anaerobic digestion process is a promising solution to counteract environmental problems, future scientific studies must focus on the stabilization, control, and management of each of the parameters of this process, which allows users to have easy access to renewable energy source technology with a comprehensive and inexhaustible long-term solution [12].

Thus, the present work aimed to evaluate the potential of fruit and vegetable waste, such as pumpkin peel (Cucurbita argyrosperma huber), tamarind peel (Tamarindus indica), corn cob leaves (Zea mays), and fecal waste from cow, sheep, and poultry coming from the municipality of Suchiapa, Chiapas, Mexico, for the production of biogas through for the anaerobic digestion.

2. MATERIALS AND METHODS

This research work was developed in the chemistry and food science laboratories of the Polytechnic University of Chiapas, located in the municipality of Suchiapa, localization at 16° 35' 0” north latitude and 93° 8' 0” west longitude, in the state of Chiapas, Mexico.

Dry samples of each of the following fruit and vegetable residues (substrate) were collected for the tests carried out in this investigation: pumpkin peel (Cucurbita argyrosperma huber), tamarind peel (Tamarindus indica) and corn cob leave (Zea mays) stored in sterile brown paper bags at a temperature of 25 °C, before determining humidity. Subsequently, for the rest of the tests, the residues were stored at 4 °C based on the sample preparation technique described in NMX-AA-52-1985 [13]. In contrast, fecal residues (anaerobic inoculum) from cows, sheep, and poultry were collected in semi-solid form in sterile sacks to store them in the same temperature condition mentioned above. It is worth noting that all organic waste was collected from the orchards and agricultural stables in the municipality of Suchiapa, located between the geographic coordinates already mentioned.

3. EXPERIMENTAL SECTION

3.1. Characterization of Organic Waste

The organic waste used in this study was characterized through bromatological and physicochemical analysis, including the determination of Hydrogen Potential (pH), Chemical Oxygen Demand (COD), Total Solids (TS), Total Volatile Solids (TVS), Total Volatile Solids/Total Solids ratio (TVS/ TS), total carbon (C), total nitrogen (N), and the Carbon/ Nitrogen ratio (C/N) following the procedures established by the standards described in Table 1.

3.2. Experimental Design for Biogas Production

The experimental design strategy, as described in Table 2, consisted of a single-factor experimental design, performing the Analysis of Variance (ANOVA) using Fisher's, Tukey's, and Duncan's LSD tests, which corresponded to the methane production in mL during a digestion time of approximately 30 days, to determine significant differences between treatments. The experiment consisted of 10 treatments and 3 replicates for each treatment to obtain 30 experimental runs. In this study, a reliability analysis of the variance was conducted using RStudio software version 4.3.1 to get a single response variable.

The treatments M1, M2, and M3 consisted of 45 grams of fruit and vegetable waste—specifically pumpkin peel, tamarind peel, and corn cob, along with cow, sheep, and poultry manure in the same concentrations. For treatment M4, the three fruit and vegetable wastes were maintained at a concentration of 36 grams, including cow and sheep manure, at equal concentrations. Treatment M5 and M6 maintained the same conditions as treatment M4; however, for treatment M5, the fecal waste comprised cow and poultry manure, and in treatment M6, the fecal waste was made up of sheep and poultry manure. Treatment M7 incorporated the three types of fruit and vegetable waste and the three types of livestock fecal waste at a concentration of 30 grams per organic waste. Ultimately, treatments M8, M9, and M10 individually analyzed livestock fecal waste of cows, sheep, and poultry to evaluate the biogas production that each of these treatments could produce.

3.3. Establishment of Anaerobic Digestion

The anaerobic digestion process was carried out in 1.8 L tanks. For this purpose, a biodigester was designed based on a modified version of a discontinuous flow biodigester according to Cardenas C., 2022 [19], which consisted of a vacuum-sealed high-density polyethylene tank with a neoprene lid (to maintain anaerobic conditions). A working volume of 1.2 L was maintained, adding both the substrate and the an-

| Parameter | Standard or Technique |

|---|---|

| pH | NMX-AA-25-1984 [14] |

| Chemical Oxygen Demand (COD) | Standard Methods for the Examination of Water and Wastewater APHA/AWWA/WEF 5220D [15] |

| Total Solids (TS) | NMX-AA-034- SCFI-2015 [16] |

| Total Volatile Solids (TVS) | NMX-AA-034- SCFI-2015 [16] |

| Total Volatile Soils/Total Solids ratio (TVS/TS) | NMX-AA-034- SCFI-2015 [16] |

| Total Carbon (C) | Organic Elemental Analyzer Thermo Scientific Flash 2000 C-N Soils Analyzer [17] |

| Total Nitrogen (N) | Organic Elemental Analyzer Thermo Scientific Flash 2000 C-N Soils Analyzer [17] |

| Carbon/Nitrogen ratio (C/N) | NMX-AA-067-1985 [18] |

| Number of Treatments | Pumpkin Peel (g) | Tamarind Peel (g) | Corn Cob Leaves (g) | Cow Manure (g) | Sheep Manure (g) | Poultry Manure (g) |

|---|---|---|---|---|---|---|

| M1 | 45 | 45 | 45 | 45 | - | - |

| M2 | 45 | 45 | 45 | - | 45 | - |

| M3 | 45 | 45 | 45 | - | - | 45 |

| M4 | 36 | 36 | 36 | 36 | 36 | - |

| M5 | 36 | 36 | 36 | 36 | - | 36 |

| M6 | 36 | 36 | 36 | - | 36 | 36 |

| M7 | 30 | 30 | 30 | 30 | 30 | 30 |

| M8 | - | - | - | 180 | - | - |

| M9 | - | - | - | - | 180 | - |

| M10 | - | - | - | - | - | 180 |

| Organic Waste | COD (g/L) |

TS (g/L) |

TVS (g/L) | TVS/TS (g/g) | pH |

C (%) |

N (%) |

C/N |

|---|---|---|---|---|---|---|---|---|

| Pumpkin peel | 0.9± 0.0 | 51.8 ± 4.7 | 30.9 ± 3.5 | 0.6 ± 4.1 | 9.3 ± 0.0 | 38.4 ± 0.3 | 2.2 ± 0.0 | 17.0 ± 0.2 |

| Tamarind peel | 1.0± 0.0 | 28.0 ± 1.5 | 25.7 ± 0.9 | 0.9± 1.2 | 3.5 ± 0.0 | 41.1± 0.0 | 1.8± 0.0 | 21.8 ± 0.0 |

| Corn cob leaves | 1.1± 0.0 | 6.6± 0.4* | 7.2 ± 0.6 | 0.9± 0.5 | 5.7± 0.0 | 41.8± 0.1 | 1.7± 0.1 | 24.3± 0.1 |

| Cow manure | 1.0 ± 0.0 | 22.4± 1.9 | 13.7± 0.7 | 0.6± 2.7 | 9.0± 0.0 | 31.0 ± 0.0 | 2.4± 0.2 | 14.3± 0.1 |

| Sheep manure | 0.9± 0.0 | 24.5 ± 4.3 | 16.7± 2.7 | 0.6± 3.5 | 8.6 ± 0.0 | 31.6± 0.0 | 2.4± 0.1 | 12.9 ± 0.0 |

| Poultry manure | 0.7± 0.0 | 49.8 ± 4.6 | 27.1± 3.7 | 0.5± 4.1 | 7.6± 0.0 | 23.0± 0.0 | 1.9 ± 0.0 | 11.6± 0.0 |

aerobic inoculum. In addition to using a fixed volume of 180 grams of organic matter from the mixture design described in Table 2 of the experimental design, the agitation applied to the biodigesters was performed manually at room temperature of 36 ± 2 °C, they were sealed with Teflon tape and heat-shrink seals for applying the thermofusion process, which consists of assembling the parts of the biodigesters with heat as mentioned by Camarena et al., 2024 [20], to avoid possible leaks, which can not only result in the loss of the biogas produced; but also in significant environmental and safety consequences.

3.4. Methane Quantification

The CH4 gas quantification was monitored simultaneously throughout the entire biogas production kinetics, measuring each treatment daily during the 30 days of digestion retention. This process was carried out using the volumetric displacement method, which is based on the quantification of the volume of CH4 produced during the anaerobic digestion retention process by using a 1N NaOH solution in a range of 15 to 20 g/L which allows the CO2 present in the biogas to be converted into sodium carbonate (NA2CO3) [21].

3.5. Calculation of the Specific Methanogenic Activity of Anaerobic Inoculum

Specific Methanogenic Activity (SMA) corresponds to the maximum methane production and the rate of organic matter consumption expressed in g COD/g TVS*day [22]. SMA coefficients can be expressed in different ways, such as mL CH4/g TVS*day or g COD/g TVS*day. The latter form will be used in this study, which is known as substrate organic loading based on COD, using Eq. (1).

|

(1) |

Where:

SMA= Specific Methanogenic Activity in g COD CH4/g TVS*day.

CMP= Cumulative Methane Production in mL CH4/day.

TVS = Total Volatile Solids (TVS) concentration in the inoculum in g/L.

V = Volume of inoculum used in L.

SCFM = Stoichiometric Conversion Factor of Methane (350 mL CH4/g COD).

4. RESULTS AND DISCUSSION

4.1. Fromatological and Physicochemical Characterization of Organic Waste

The results of the carbon and nitrogen ratio of the tamarind husk and corn cob leaves waste are presented in Table 3, with a C/N ratio of 21.87 and 24.34, respectively. The study by Castro et al., 2021 [23] initially indicated that the anaerobic digestion process benefits from the adequate growth of the microorganisms in the anaerobic inoculum during the methanogenesis stage as the C/N ratio values fall within the optimal range established in the FAO Biogas Manual [6]. These findings positioned carbon as the indispensable source of energy for the microorganisms present in the anaerobic digestion process and nitrogen as the necessary element for their cellular duplication [24].

In contrast, the results of the bromatological and physicochemical characterization of the organic waste also included the TVS/TS ratio, which represents the percentages of biodegradable organic matter capable of being transformed into biogas. For this parameter, the values of 60, 92, and 95% were obtained for pumpkin peel, tamarind peel, and corn cob leaves, respectively. According to Ren et al. (2003) [25], the optimal value of the TVS/TS should be higher than 50%; therefore, the results indicate that the substrates contain a sufficient amount of assimilable organic matter to support anaerobic microbial activity and the production of biogas.

The assessment of the COD and the TVS/TS ratio for each substrate serves as an indicator of the biodegradability of the organic matter and its subsequent conversion into biogas. Table 3 shows that the corn cob leaf residue contained 1.13 grams of COD/L, a value higher than those obtained from the pumpkin peel and tamarind peel residues. The higher resulting value indicates that the corn cob leaf residue is the substrate that could present a better effect in terms of substrate/inoculum ratio for obtaining biogas [26]. However, the COD values of the initial characterization obtained in each of the residues do not necessarily indicate that all the organic matter contained is fully biodegradable. Therefore, the SMA of the anaerobic inoculum was calculated to determine the potential differences when each of the substrates was mixed with various residues used as anaerobic inocula.

| Treatments | Initial pH | Final pH | TS (g/L) | TVS (g/L) | TVS/TS (g/g) | C (%) | N (%) | C/N | Statistical Difference** |

|---|---|---|---|---|---|---|---|---|---|

| M1 | 6.9 ± 0.0 | 5.0 ± 0.0 | 27.26 ± 2.2 | 19.4 ± 1.4 | 0.7 ± 1.8 | 39.6 ± 0.1 | 2.0 ± 0.1 | 19.0± 0.1 | A |

| M2 | 7.1 ± 0.0 | 4.9 ± 0.0 | 27.7 ± 2.7 | 20.1± 1.9 | 0.7± 2.3 | 39.7 ± 0.1 | 2.0 ± 0.0 | 19.0 ± 0.0 | BE |

| M3 | 6.7 ± 0.0 | 5.2 ± 0.0 | 34.1 ± 2.8* | 22.7 ± 2.2 | 0.6± 2.5 | 37.6 ± 0.1 | 1.9 ± 0.2 | 19.1 ± 0.2 | C |

| M4 | 7.0± 0.0 | 5.0 ± 0.0 | 26.7± 2.6 | 18.9 ± 1.7 | 0.7 ± 2.1 | 38.0± 0.1 | 2.1± 0.1 | 17.6± 0.1 | D |

| M5 | 7.1 ± 0.0 | 5.3± 0.0 | 31.7 ± 2.6 | 20.9 ± 1.9 | 0.6 ± 2.3 | 36.3± 0.1 | 2.0 ± 0.1 | 17.6 ± 0.1 | EB |

| M6 | 7.1 ± 0.0 | 5.1 ± 0.0 | 32.1 ± 3.1 | 21.5 ± 2.3 | 0.6± 2.7 | 36.4 ± 0.1 | 2.0 ± 0.0 | 17.6 ± 0.1 | F |

| M7 | 7.5 ± 0.0 | 4.9 ± 0.0 | 30.5 ± 2.9 | 20.8 ± 2.0 | 0.7 ± 2.5 | 35.5± 0.1 | 2.1± 0.1 | 16.7 ± 0.1 | G |

| M8 | 7.7 ± 0.0 | 7.8 ± 0.0 | 22.4 ± 1.9 | 13.7 ± 0.7 | 0.6± 1.3 | 31.0± 0.0 | 2.4± 0.2 | 14.3 ± 0.1 | H |

| M9 | 8.4 ± 0.0 | 6.1 ± 0.0 | 24.5 ± 4.3 | 16.7 ± 2.7 | 0.6± 3.5 | 31.6 ± 0.0 | 2.4 ± 0.1 | 12.9 ± 0.0 | I |

| M10 | 8.2 ± 0.0 | 5.8± 0.0 | 49.8 ± 4.6 | 27.1± 3.7 | 0.5± 4.1 | 23.0 ± 0.0 | 1.9± 0.0 | 11.6± 0.0 | J |

4.2. Physicochemical Characterization of the Experimental Treatments

Table 4 presents the results of the physicochemical characterization for the parameters' including initial pH, TS, TVS, and the TVS/TS ratio for each of the formulated treatments at the onset of the anaerobic digestion process. Additionally, pH was monitored at the end of the retention time of the digestion to identify the decrease in this parameter and determine the potential changes that could modify the stages of the digestion process. Therefore, the pH was not regulated at the beginning of the anaerobic digestion. However, the pH of each material and the mixture was evaluated at the beginning of the digestion, as shown in Tables 3 and 4.

As mentioned above, pH adjustments are performed at the beginning of each anaerobic digestion process; however, for this experimental research, such adjustments were omitted because most of the treatments presented an initial pH between optimal ranges (6.8-7.4). When mixing substrate-anaerobic inoculum, the following presented optimal initial pH with values of M1: 6.98, M2: 7.11, M4: 7.07, M5: 7.12 and M6: 7.17, Treatment M3 presented a pH of 6.78 below the optimal range, and treatments M7, M8 and M9 with pH higher than the optimal range, with the following values of 7.73, 8.46 and 8.29, respectively. The pH value in biodigesters determines the production of biogas and its composition [6].

According to the study by Parra, et al. 2014 [27], the pH determination in the anaerobic digestion process expresses the degree of acidity or alkalinity under which the organic matter is biodegradable. If the pH is not in the optimal range, adjustments are required to maintain the stability of the process. When the substrates present high concentrations of acidic organic matter, they are highly fermentable and tend to acidify the medium, which can inhibit the action of microorganisms and eventually cause the failure of the digestion process. These values also express the increase and production of Volatile Fatty Acids (VFAs) associated with the formation of long-chain or branched volatile fatty acids, which could prolong the adaptation times of microorganisms present in anaerobic inoculum during the hydrolysis stage [28]. According to Deubleien., et al. 2008 [29], adjusting the pH between the optimal range of 6.8-7.4 is essential, not only for the hydrolysis stage but also for the methanogenesis stage. Generally, these pH values favor the adaptation conditions of bacteria such as Methanosarcina sp, capable of producing CH4 even in pH conditions lower than 6.5.

The LSD, Tukey, and Duncan tests conducted at an alpha of 0.05 showed that the mixtures M2 and M5 do not present statistically significant differences in terms of optimal pH parameters. However, when relating these mixtures with the result of the rest of the treatments, there is a statistically significant difference resulting in a p-value < 0.05.

Table 4 shows a comparison between the initial and final pH parameters of the anaerobic digestion process for each of the experimental treatments analyzed, where a neutral pH was expected for all cases. The results indicate that the final pH of the treatments was not neutral and below the optimal value (pH: 6). According to the existing literature, a decrease in pH values below 6 may indicate that the biogas produced is low in methane content and, thereby, possessing energy characteristics that differ from the intended purpose of this research (generating biogas for injecting into the natural gas network) thus it is recommended to conduct a detailed analysis of the composition of the biogas generated in this experiment [30].

On the other hand, the results shown in Table 4 concerning the TVS/TS ratio indicate that the content of available organic matter in most treatments is above 60% and there is a large amount of organic matter biodegradable for the consortium microorganisms present in the anaerobic inoculum [11]. Treatment with a value of 0.55 g/g equivalent of TVS/ TS at 55% is within the optimal range of 40-60% concerning TVS/TS. As mentioned above, the high content of organic matter in the substrates, when digested by microorganisms without prior dilution, would slow down the anaerobic digestion process; therefore, a working volume of 1.2 L was maintained so as not to affect the efficiency and production of biogas [31].

Finally, a detailed analysis of the results in Table 4 regarding the C/N ratio reveals that none of the treatments meets the initial requirements for this parameter. According to the FAO Biogas Manual, the optimal range to establish the anaerobic digestion process must be between 30:1 and 20:1. By having concentrations below the C/N ratio of 20:1, the process could be affected by the inhibition of the microbiological activity of the anaerobic inoculum and cause excessive production of ammonia content within the biodigester, which in large quantities is toxic and inhibits the digestion process [6]. In general, if the treatments do not meet this parameter, to achieve an optimal C/N ratio, it is necessary to mix them with other types of organic waste that contain the appropriate proportions to obtain the optimal C/N ratio.

4.3. Experimental Process of the Specific Methanogenic Activity of Anaerobic Inoculum

For this study, the results of the SMA were used to analyze and quantify the activity of the methanogenic population within the anaerobic inoculum in response to the biomass present in the different substrates. This evaluation aimed to assess microbial performance in the presence of potentially toxic or inhibitory compounds. On the other hand, Lemos-Chernicharo., et al. 2020 [32] established that the calculation of the SMA can not only determine the degree of biodegradability of the substrates but also estimate possible pH changes in the medium, in addition to determining the maximum organic loading capacity applicable to any other type of anaerobic inoculum beyond those used in this research work.

To clarify differences in SMA between the different anaerobic inoculum, Table 5 compares the different inoculum that reached their exponential phase in CH4 production from day 6 to day 11. However, for the calculation of SMA, data from days 8 and 9 were taken because they contained the highest values of CH4 production in the exponential phase of anaerobic digestion of each treatment.

| Anaerobic Inoculum | SMA (g COD CH4 /g TVS*day) | Temperature °C | Statistical Difference** |

|---|---|---|---|

| Cow manure | 0.58± 0.3 | 37± 0.1 | CD |

| Sheep manure | 0.52± 0.1 | 37± 0.1 | AC |

| Poultry manure | 0.34± 0.2 | 37± 0.2* | AB |

The maximum SMA of the anaerobic inoculum used in this study reached a conversion rate of 0.58 g COD CH4/g TVS*day, as observed with the cattle manure substrate. According to Jiménez et al., 2015 [33] and Van L. et al., 1996 [34], the optimal values of the SMA range between 0.27 to 1.45 g COD CH4/g TVS*day. Therefore, the three types of anaerobic inoculum used in this experiment are within the optimal range, as shown in the results in Table 5. In the study conducted by Arano et al., 2023 [35], a maximum SMA of 0.22 and 0.19 g COD CH4/g TVS*day was presented for the cows and poultry manure inocula, respectively. When comparing these results, it is evident that the SMA values obtained in this work are higher than those reported by the referenced authors, indicating a high biodegradability capacity and potential to assimilate the greater organic load across various substrates. However, specific data on the SMA of sheep manure inoculum is limited in the literature. However, the 0.52 g COD CH4 /g TVS*day of the SMA described in Table 4 for this type of inoculum is within the optimal range established for the anaerobic digestion process under optimal conditions.

Based on the statistical analysis performed using ANOVA with the LSD, Tukey, and Duncan tests, no statistically significant differences were found between treatments as the p-value is greater than 0.05. These results imply a high energy efficiency in the production of methane when mixing any of the three types of inoculum (cow, sheep, and poultry manure) with the three fruit and vegetable residues (pumpkin peel, tamarind peel, and corn cob leaves) to formulate the treatments of the proposed experimental design.

4.4. Methane Production Behavior During the Anaerobic Digestion Process

The kinetics of biogas production are closely related to the growth of microorganisms present in the anaerobic digestion process, which defines the rate of CH4 production and the degradation of organic substrates. In addition, it is the basic tool to scale up laboratory biotechnological processes to an industrial scale, allowing to predict the yield and production of biogas [36].

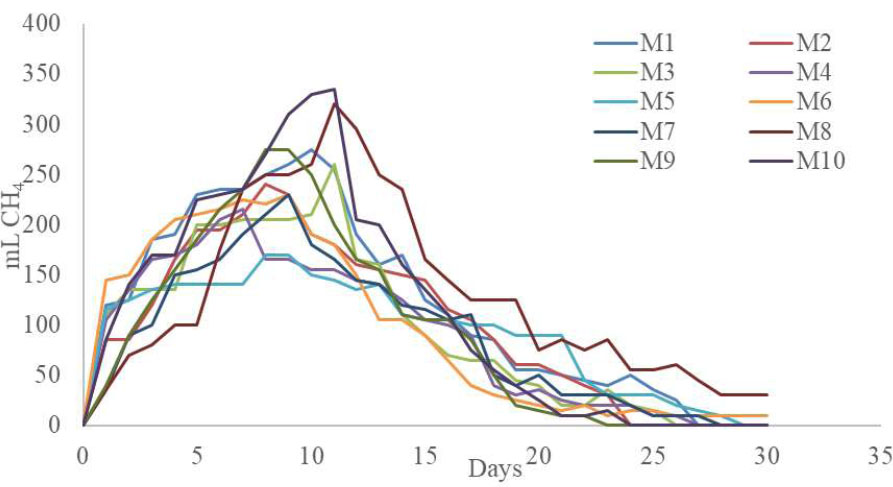

Therefore, for each anaerobic digestion process, it is important to evaluate the bacterial growth inside the biodigesters from the start of the typical curve, graphed to have greater control over the biogas production process, where three stages are evaluated, the start-up, the stabilization, and the decline [6]. Fig. (1) presents the results of the methane production kinetics from the different treatments described in the experimental design of this study.

As mentioned above, the biogas measurement was conducted using the volumetric displacement method to quantify the volume of methane produced during the anaerobic digestion process. This method involved the use of displacing solution–1N NaOH in a range of 15 to 20 g/L—due to its ability to react with the CO2 present in the biogas and form sodium carbonate (Na2CO3) [21]. This reaction allowed an approximate measurement of the volume of methane produced in each of the treatments. The results in each of the graphs show that substrate–inoculum assimilation for biogas production from day 6 to 11. During this period, stability for the bacterial consortium is required to assimilate the load of organic matter present in the substrates. The results obtained by Briseño. 2017 [21], in the same retention time of anaerobic fermentation (30 days), indicate that the assimilation of organic matter occurs between day 14 and day 25, similar to that reported by Quechulpa et al., 2021 [37], who report the assimilation of organic matter through the use of domestic biodigesters from day 13 to day 21, comparing the results, these would indicate accelerated assimilation for the methanogenic stage of the anaerobic digestion process.

To improve the results of the biogas production kinetics curves of this study presented in Fig. (1), a bacterial consortium of an active, stable biodigester rich in methanogenic bacteria should be added to shorten the start-up stage and improve the stabilization stage since the curves presented would be expressing low assimilation of the substrate with anaerobic inocula [6].

4.5. COD Removal Efficiency and Total Methane Production

Generally, COD indicates the amount of oxygen required to oxidize the organic and inorganic matter present in wastewater. In this study, it was important to evaluate the COD concentrations to identify the level and/or percentage of biodegradable organic matter in each designed treatment [38]. Therefore, the efficiencies of organic matter consumption during methane production in each treatment were evaluated using the initial and final COD of the anaerobic digestion process as a variable. The results described in Table 6 allowed for permanent control over each of the treatments, identification of the percentages of removal from the biodigesters, and evaluation of the efficiency and performance of biogas production during the digestion process.

The M3 and M10 treatments presented the highest efficiency in removing organic matter, with a value of 71% and 97%, respectively. This is attributed to the capacity of poultry manure to facilitate organic matter degradation, as demonstrated by the percentages of removal of this anaerobic inoculum.

Regarding methane production, the ANOVA used with the LSD, Tukey, and Duncan tests showed no statistically significant difference between the experimental treatments due to the normal distribution or randomness in the data extracted during the experiment. These results indicated that the 10 designed treatments could generate the same performance in terms of biogas production.

The M6 treatment obtained a 67% COD removal, exceeding the reported 64.9% COD removal in plant waste after 20 days of retention of the anaerobic digestion process [39]. In comparison, the rest of the treatments presented lower removal below 59% in COD degradation. Therefore, it is recommended to perform a detailed analysis regarding the chemical composition of these treatments (M1, M2, M4, M5, M7, M8, and M9), according to Crombet C. et al., 2016 [40], the variation in COD removal in the treatments attributed to the characteristics and composition of the anaerobic inoculum.

As observed in Table 6, the removal of COD in the treatments where only anaerobic inocula are evaluated presented a greater degradation of organic matter, which indicates that the treatments need to have a close substrate-inoculum relationship to be efficient and to optimize the degradation of organic matter to achieve high methane production [41].

Similarly, in the studies reported by Placencia R., 2014 [8], evaluations were conducted on methane production from cattle and pig manure digested with agroindustrial waste, which shows that cattle manure has a greater potential for methane production, presenting a biogas volume of 860 L of methane; on the other hand, a study carried out by Pimentel., et al. 2019 suggested sheep manure to be the best substrate for biogas production with a yield of 50 L of methane [41]. When comparing the results obtained in this research project, it is estimated that by generating mixtures between agroindustrial organic waste and any of the two types of manure already mentioned, high biogas production yields are produced with quantities of up to 850 L of CH4 [8].

Although the percentage may vary by source, organic matter typically constitutes the majority component of Municipal Solid Waste (MSW). Chiapas' significant agricultural activity and the composition of its domestic waste represent both a challenge and an opportunity.

Methane production of the different experimental treatments.

| Treatments | Initial COD (g/L) | Final COD (g/L) | Removing Organic Matter (%) | Methane Production (CH4 mL) | Statistical Difference** |

|---|---|---|---|---|---|

| M1 | 1.2 ± 0.0 | 0.5 ± 0.0* | 59 | 3645 | A |

| M2 | 1.1 ± 0.0 | 0.5 ± 0.0 | 56 | 3050 | B |

| M3 | 1.1 ± 0.0 | 0.3 ± 0.0 | 71 | 2920 | C |

| M4 | 1.2 ± 0.0 | 0.4 ± 0.0 | 61 | 2730 | D |

| M5 | 1.2 ± 0.0 | 0.5 ± 0.0 | 57 | 2815 | E |

| M6 | 1.2 ± 0.0 | 0.4 ± 0.0 | 67 | 2910 | F |

| M7 | 1.1 ± 0.0 | 0.6 ± 0.0 | 43 | 2685 | G |

| M8 | 1.0 ± 0.0 | 0.6 ± 0.0 | 44 | 4250 | H |

| M9 | 1.1 ± 0.0 | 0.5 ± 0.0 | 54 | 2875 | I |

| M10 | 1.0 ± 0.0 | 0.0 ± 0.0 | 97 | 3540 | j |

If not properly managed, this waste can contribute significantly to environmental problems such as soil and water pollution, greenhouse gas (methane) emissions, and public health issues.

However, given the large volume of organic waste generated, Chiapas has enormous potential to implement sustainable management strategies that can transform this “waste” into valuable resources. Anaerobic digestion, for instance, not only generates biogas—a renewable energy source—but also produces a digestate that can be used as fertilizer. Therefore, this study highlights the adequate management of agricultural waste through the control of variables that guarantee the appropriate production of biogas.

In addition, it promotes investment in research and development, technology transfer, financial support for municipalities, and the creation of a regulatory framework that incentivizes the management of organic waste, all of which are essential to strengthen the management of waste in Mexico and move toward a more circular and sustainable economy.

CONCLUSION

In conclusion, the physicochemical analysis confirmed that the fruit and vegetable waste, pumpkin peel, tamarind peel, and corn cob leaves in their TVS/TS ratio with values of 60%, 92%, and 95%, respectively are easily degraded waste due to their high amount of organic matter. However, this does not ensure that the agroindustrial waste generates a high yield in terms of CH4 production. Therefore, it is necessary to perform the SMA calculations of the anaerobic inocula to maximize the potential for obtaining methane-rich biogas.

Thus, when calculating the SMA of the inocula cow, sheep, and poultry manure, they reached a maximum conversion rate of 0.58, 0.52, and 0.34 g CH4/g TVS*day, respectively, which is optimal for the anaerobic digestion processes that are carried out during this work.

Chemical oxygen demand was used to assess the percentage of organic matter removal by the anaerobic digestion process in each of the treatments, yielding the following values: M1 - 59%, M2 -56%, M3 - 71%, M4 - 61%, M5 - 57%, M6 - 67%, M7 - 43%, M8 - 44%, M9 - 54%, with M10 - 97%, demonstrating the greatest removal of efficiency.

At the end of the anaerobic digestion process, the accumulated biogas production in the treatments was 36,645 mL in M1, 3,050 mL in M2, 2,920 mL in M3, 2,730 mL in M4, 2,815 mL in M5, 2,910 mL in M6, 2,685 mL in M7, 4,250 mL in M8, 2,875 mL in M9, and 3,540 mL in M10. These results were obtained under mesophilic temperature conditions of 36 ± 2 °C, without pH control, during a hydraulic retention time of 30 days.

These findings support the anaerobic digestion technology as a sustainable alternative to the use of organic waste. However, to improve the biogas production and the stability of the anaerobic digestion process, variations are necessary in the substrate/inoculum ratio, the temperature, and the pH. Additionally, the inclusion of some automated equipment that provides constant agitation to the biodigesters to improve the performance and, the quality of the biogas.

This study concluded that fruit and vegetable residues and livestock fecal waste can be used for anaerobic digestion, achieving improved methane production with controlled pH. The lack of control over these variables prevented the treatments from fulfilling the hypothesis that the substrate-inoculum ratio would produce the highest biogas. A high value of 4250 mL of CH4 was observed in treatment M8, where there was no substrate-inoculum ratio but only the use of microbial inoculum.

AUTHORS’ CONTRIBUTIONS

The authors confirm their contribution to the paper as follows; Y.D.C.P.L.: Analysis and interpretation of results; Y.S.R., S.S.T., R.R.H., A.G.Z.C.: Draft manuscript; H.V.B., P.L.D.P: Visualization; D.A.C.Y.: Investigation. All authors reviewed the results and approved the final version of the manuscript.

LIST OF ABBREVIATIONS

| N | = Nitrogen |

| LCFA | = Long-Chain Fatty Acids |

| LGPGIR | = General Law for the Prevention and Comprehensive Management of Waste |

| CO2 | = Carbon Dioxide |

| GHG | = Greenhouse Gas |

| COD | = Chemical Oxygen Demand |

| TS | = Total Solids |

| TVS | = Total Volatile Solids |

| TVS/TS | = Total Volatile Solids/Total Solids Ratio |

| C | = Carbon |

| N | = Nitrogen |

| C/N | = Carbon/Nitrogen Ratio |

| ANOVA | = Analysis of Variance |

AVAILABILITY OF DATA AND MATERIALS

The data supporting the findings of the article is available in the [Zenodo] at [https://zenodo.org/records/15757732], reference number [Sánchez Roque, Y., Pérez-Luna, Y. del C., Saldaña Trinidad, S., Berrones Hernández, R., Zenteno Carballo, A. G., Vilchis, H., Lopez De Paz, P., & Castillejos Yuca, D. A. (2025). Conjunto de datos del articulo Optimización de los procesos de digestión anaeróbica de residuos orgánicos en Chiapas, México, para la producción de biogás. Zenodo. https://doi.org/10.5281/zenodo.15757732].

FUNDING

This research was funded by the Secretariat of Science, Humanities, Technology, and Innovation (SECIHTI), Mexico. CVU number: 1144292.

ACKNOWLEDGEMENTS

The authors would like to thank the producers who collaborated by providing organic waste for this research work, as well as the Polytechnic University of Chiapas (UP Chiapas) for providing the spaces for its chemistry and food science laboratories of the Academic Program in Agroindustrial Engineering.