RESEARCH ARTICLE

Effect of Harvesting Time, Curing and Storage Methods on Storability of Garlic Bulbs

Bizuayehu Desta1, 2, *, Kebede Woldetsadik1, Wassu M. Ali1

Article Information

Identifiers and Pagination:

Year: 2021Volume: 15

First Page: 36

Last Page: 45

Publisher ID: TOBIOTJ-15-36

DOI: 10.2174/1874070702115010036

Article History:

Received Date: 2/10/2020Revision Received Date: 4/3/2021

Acceptance Date: 19/3/2021

Electronic publication date: 24/05/2021

Collection year: 2021

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Background:

Farmers are forced to store garlic bulbs for a long period due to occasional excess production or to save bulb seeds for next season planting, but the bulbs often lose their viability and vigour due to sprouting ahead of planting time.

Objective:

The research was conducted to evaluate the effects of three harvest stages (60, 80, and 100% top fall), two curing levels (non-cured and cured bulbs), and three storage methods (floor, shelf, and net bag) on storability of garlic variety ‘Tseday’ at Haramaya University, and Tony farm (Dire Dawa) during 2014-15.

Methods:

The experiment was laid out in a Randomized Complete Block Design with three replications at both sites.

Results:

Significant variations in the storability of bulbs were evident due to harvest stages, curing, and storage methods. Harvesting of garlic bulbs at 100% top fall considerably increased bulb yield by about 16.74% and 8.75% compared to 60 and 80% top fall, respectively. Cured bulbs showed lower fresh bulb yield as compared to non-cured bulbs. Harvesting at 80% top fall, curing and storing bulbs on a shelf or in a net bag showed reduced weight and diameter loss of bulbs as compared to the other treatments. Bulbs harvested at 80% top fall and cured had significantly higher dry matter content than the rest. The highest sprouting percentage was recorded for 60% top fall harvested and non-cured bulbs, while the least was observed in 80% top fall harvested and cured bulbs.

Conclusion:

The result of this study has shown that harvesting at 80% top fall, curing, and storing bulbs on a shelf or in a net bag leads to a good yield and postharvest quality and effective storability of garlic bulbs under ambient storage conditions.

1. INTRODUCTION

Garlic (Allium sativum L.) is harvested when plant tops start to dry and fall, and stems (necks) have begun to soften and are partly dried [1, 2]. The maturity of garlic that can be estimated by the time of harvest is governed by its subsequent use. Harvesting at the proper stage of physiological maturity is a prerequisite to obtaining successful planting material. The early harvest of garlic produces small bulbs that exhibit rapid weight loss and cracking of the bulb wrapper skins, while delayed harvest results in loose (split), discolored and sunburned bulbs, and occasionally cloves begin to sprout. In general, both early and delayed harvesting of garlic cause deterioration in the market potential of the garlic [2, 3].

Curing is a process intended to dry off the necks, roots, and outer scale leaves of the bulbs [4] and removes excess moisture from the outer layers of the bulb prior to storage. During curing, the nutrient from the leaves moves into the bulb until the foliage is dead and the neck gets soft [5]. This gives the maximum opportunity for the growth inhibitors present in the leaves to enter the bulb and prolonged the storability and transporting of bulbs for long-distance. The dried skin provides a surface barrier to water loss and microbial infection and is desirable to the development of good color, thereby preserving the main edible tissue in a fresh state [6]. Curing also reduces shrinkage during subsequent handling and delays the sprouting period by reducing the respiration rate of the bulbs [7]. Swift [7] further reported that curing allows the development of natural dormancy and the crop to ripen before fresh consumption or long-term storage. As some workers indicated, curing can extend the storage life of onion bulbs from 3 to 9 months, depending on the variety [4].

The three most important factors in storage leading to deterioration and short shelf life of bulb crops are temperature, relative humidity, and gas composition of the storage environment. Among these, the temperature has a profound effect on the dormancy period and storage life of bulbs. Respiration rate is related exponentially to increased storage temperature and is generally a good indicator of post-harvest quality degradation [8].

In an ideal storage environment (-1 to 0°C and a Relative Humidity (RH) of 60–70%), cured and cleaned garlic bulbs can be kept for up to 12 months [9]. At room temperatures of 20-30°C, the storage life of garlic is one or two months [10]. Sprouting is most rapid at temperatures between 4 and 18°C, which is accompanied by loss of quality. The management of weight loss and decay of garlic bulbs during storage under high-temperature (>25°C) is difficult than the dormancy of bulbs. The maintenance of low humidity (no more than 65-70% RH) is critical for successful storage, as high humidity favors both decay and root growth [3, 11, 12].

Garlic is produced as a seasonal crop in Ethiopia, and sometimes there is excess production. In such conditions, the farmers either sell at a low price due to the postharvest and storage loss or keep the bulbs to sell at a good price later, but in such case, bulbs are prone to quality loss due to long storage. Not only this, farmers store bulbs for the next planting season, but the bulbs often lose their viability and vigor due to sprouting ahead of planting time as the bulbs start sprouting as soon as they complete their dormancy period. Many factors, such as bulb maturity, moisture content of the bulb, curing and drying method, storage condition, mainly temperature, and relative humidity, are associated with sprouting, disease incidence, rotting, and physiological weight loss. Among other postharvest practices that can enhance the shelf life of garlic, the optimum time of harvesting, curing for some days, and keeping at good storage condition are the major ones. Careful handling and the choice of a suitable storage method for the cultivar type in question are vital to ensure that the product retains its quality until it reaches the consumer for varied end uses. In addition, retaining an attractive appearance has a considerable contribution in increasing the competitiveness of the product in retail markets [5]. In this regard, Diriba et al. [13] and Getenesh et al. [14] evaluated the effect of one or more factors on the shelf life of garlic and onion bulbs, respectively, in Ethiopia. However, the generated information from these research works is either not sufficient or did not consider harvesting time, curing, and storage methods altogether in the experiment to evaluate the effect on the storability of bulbs. Hence, this research was conducted with the objective of determining the optimum time of harvesting, curing, and storage methods for better storability of garlic bulbs.

2. MATERIALS AND METHODS

2.1. Experimental Area and Materials

The experiment was conducted at Haramaya University and Tony farm (Dire Dawa), the research site of Haramaya University, Ethiopia. Haramaya University is located at 9o 26’ N latitude and 42o 03’ E longitude and an altitude of 2,002 m.a.s.l. Haramaya is situated in the semi-arid tropical belt of Eastern Ethiopia. The area has a bimodal rainfall distribution; the short rainy season is from March to May, and the main rainy season is from July to September. Tony farm is located at 9o27’- 9o49’N latitude and 41o38’-42o9’E longitude and an altitude of 1,160 m.a.s.l. During the experimental (storage) period, the mean monthly minimum and maximum temperatures were 8.95°C and 25.08°C, respectively, and the average relative humidity is 45.92% while in Tony farm, the mean monthly minimum and maximum temperatures were 27.25°C and 31.9°C, respectively and the average relative humidity is 43.15%.

The garlic variety ‘Tseday’ was grown at Haramaya University for the study. Bulbs were stored in a naturally ventilated diffused light store constructed from a mesh wire wall and corrugated iron sheet roofing.

2.2. Treatments and Experimental Design

The treatments were composed of 3 × 2 × 3 × 2 factorial combinations of harvesting time (60%, 80%, and 100% top fall), curing levels (non-cured and cured-topped), storage methods (wooden shelf, nylon net bag, and floor) and storage sites [Haramaya University representing midland altitude (2,002 masl) and Dire Dawa representing lowland (1,160 masl)] with three replications. Curing and storage were done at Haramaya University and Tony farm (Dire Dawa) under ambient temperature. The duration of the storage period was one hundred twenty days for all the treatments. The treatments were laid out in a randomized complete block design (RCBD) as the experimental design where sample bulbs were harvested in a factorial arrangement.

The experimental sample bulbs were collected from the experimental plots laid out as a Randomized Complete Block Design (RCBD). The experimental land was prepared in accordance with the standard practice of Haramaya University for the crop. The land was ploughed to a depth of 25-30 cm, pulverized, and leveled. Ridges and furrows were prepared using hand tools manually. The experimental field plot size was 3.6 m2 (1.8 m x 2.0 m) with a total of 120 plants per plot with 1.5 m spacing between blocks and 1 m between plots. Sprouted cloves were planted on July 3, 2015, according to the standard planting density of 10 cm x 30 cm with 20 plants per row. Fertilizer was applied at the rate of 200 kg DAP/ha and 150 kg urea/ha, where all the recommended rate of DAP was applied at the time of planting while urea was applied in segments, one-third during planting, one-third at active vegetative growth (three weeks after plant emergence) and the rest one-third six weeks after plant emergence as a side dressing. Weeding and chemical sprays were done as per the recommendation made for the crop [15].

The first harvesting was done after 60% of the garlic tops fell (November 2, 2015), while the second and third harvests were done on November 21, 2015, and December 4, 2015, at 80% and 100% top fall, respectively. Bulbs from the central four rows were harvested and used for storage. The storage time started on November 2, 2015 and extended up to April 4, 2016. Daily storage temperature was recorded within three hours intervals. For each harvesting time, curing treatment was applied to non-cured tops, which were cured with windrowing by spreading them evenly on the ground under shade for 10 days before topping.

2.3. Data Collection

The following quality and storability data were recorded randomly after harvesting and storing bulbs at different time intervals for four consecutive months during the storage season.

2.3.1. Fresh Bulb Weight (kg/plot)

Fresh weight of bulbs was taken immediately after harvesting by cutting the tops of bulbs that did not receive curing treatment.

2.3.2. Cured Bulb Weight (kg/plot)

The cured weight of bulbs was taken immediately after curing the bulbs.

2.3.3. Bulb Dry Matter Content (%)

A homogenate sample was prepared from the bulbs at each plot. For determination of percent of dry matter, 25g of the homogenate was taken and oven-dried at a temperature of 70°C until a constant weight was obtained. Then the weight was measured using a digital balance (METTLER TOLEDO), and percent dry matter was calculated using a formula:

|

Where, DW= Dry Weight, CW=Container Weight (Paper bag), FW= Fresh Weight

2.3.4. Bulb Weight and Diameter Loss (%)

These were determined using the methods described by Waskar et al. [16]. The measurement was based on the difference in weight and diameter of bulbs at the beginning and two weeks intervals using 30 bulbs taken randomly from each treatment replication over the storage periods. The difference between the initial weight/diameter and successive weight/ diameter gave the weight and diameter losses percentages; the storability data measurements were converted to cumulative percentage losses at the successive storage weeks.

|

Where, Wi = initial weight and Wf = final weight.

2.4. Data Analysis

The collected data were subjected to analysis of variance (ANOVA) using the General Linear Model (GLM) of the SAS statistical package version 9.2. Homogeneity of variances was tested using the F-test as described by Gomez and Gomez [17]. The F-test had shown homogeneity of the variances of the two sites; therefore, combined analysis variance was computed, and results are presented accordingly. All significant pairs of treatment means were compared using the Duncan’s Multiple Range Test (DMRT) at a 5% level of significance.

3. RESULTS AND DISCUSSION

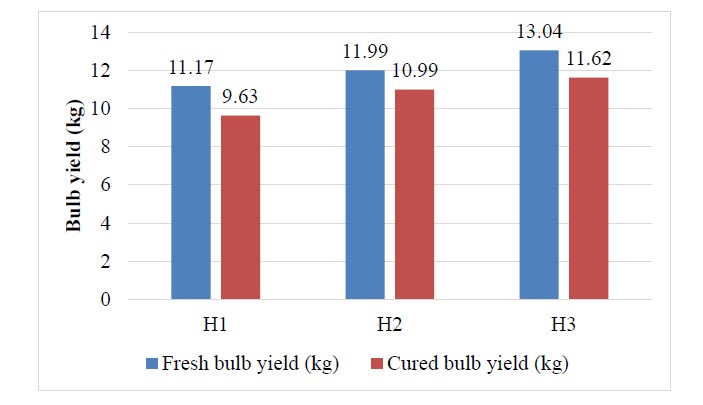

3.1. Fresh and Cured Bulb Yield

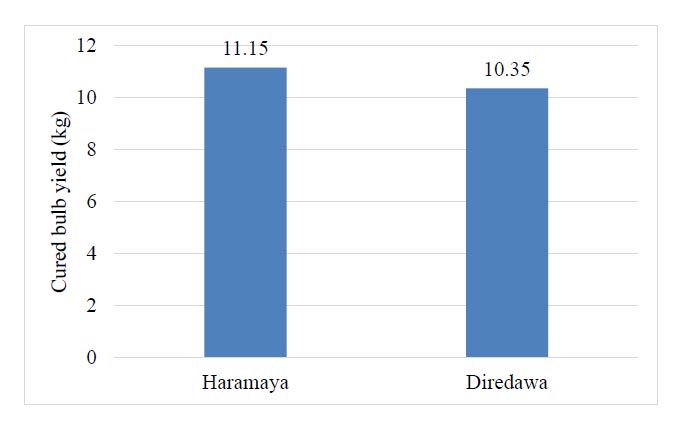

The largest fresh and cured bulb yield (13.04 and 11.62 kg, respectively) was observed at 100% top fall followed by 80% top fall harvest, while the lowest fresh and cured bulb yield was recorded from 60% top fall bulbs (Fig. 1).

It was expected that the fully matured bulbs would yield more early and mid-harvested plants because of the longer duration for photosynthates accumulation, but the fear of delaying harvest was postharvest loss during storage. Studies on the effect of harvest date on onions indicated that bulb yield increases dramatically in the fourth week before 100% top-fall [18]. They suggested that bulb onions should be harvested when or after the necks weaken and the tops fall over when the elongation of new leaves into the neck stops. The nutrients from the tops continue to increase the weight and dry matter content of bulbs. There was also higher garlic cured bulb weight at Haramaya than at Diredawa due to a lower temperature and high relative humidity that led to lower respiration rate and decreased moisture loss from the bulbs at the former site [19] (Fig. 2).

|

Fig. (1). Effect of harvesting time on fresh and cured bulb yields of garlic. |

|

Fig. (2). Effect of storage site on cured bulb yield of garlic. |

3.2. Bulb Weight and Diameter Loss

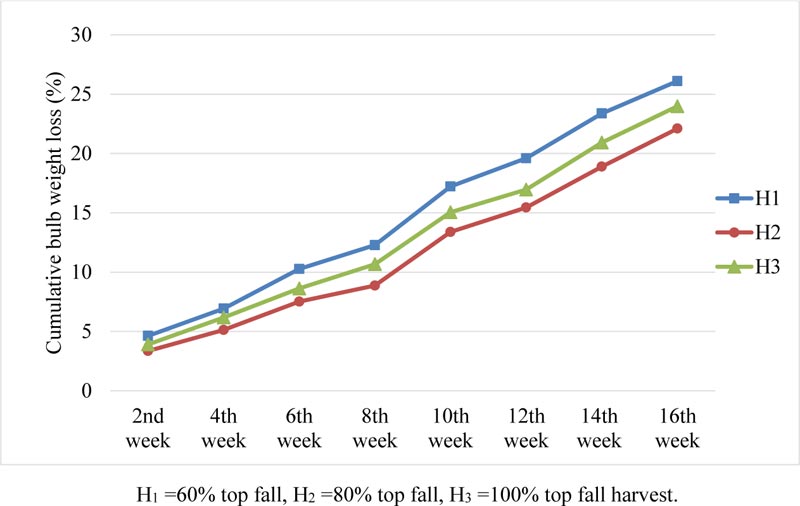

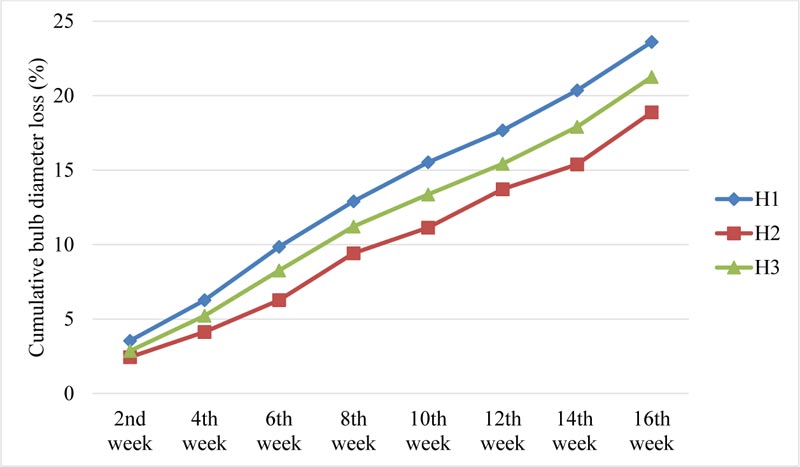

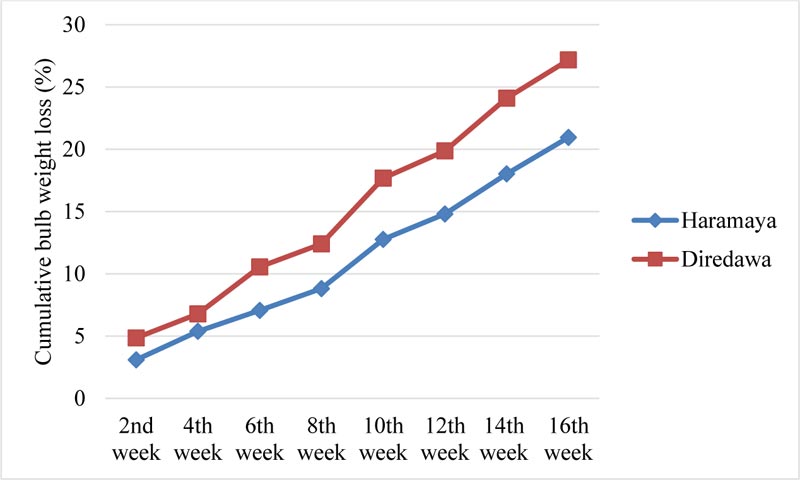

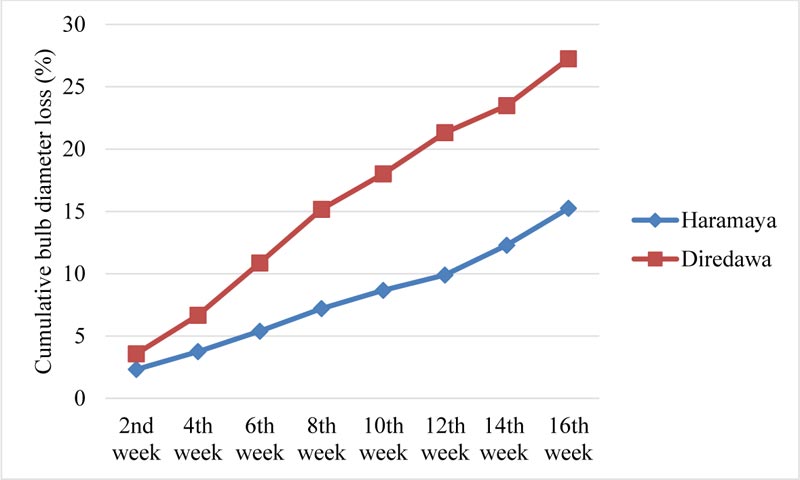

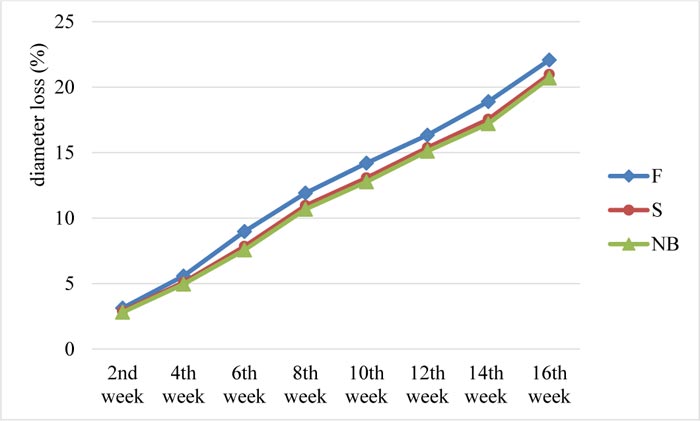

The largest weight and diameter loss was observed in bulbs harvested at 60% of top fall followed by 100% top fall harvest throughout the storage periods. The lowest percent weight and diameter losses were recorded at 80% of top fall harvested bulbs throughout all the storage weeks (Figs. 3 and 4). There was also higher garlic bulbs weight and diameter loss in Diredawa than in Haramaya that might be due to a higher temperature and low relative humidity that led to higher respiration rate and increased moisture loss from the bulbs [19]. As the storage period extends, there was an increase in cumulative weight and diameter loss in both sites (Figs. 5 and 6).

|

Fig. (3). Effect of harvesting time on weight losses of garlic bulbs at different storage weeks. |

|

Fig. (4). Effect of harvesting time on diameter losses of garlic bulbs at different storage weeks. |

|

Fig. (5). Effect of storage site on weight losses of garlic bulbs at different storage weeks. |

|

Fig. (6). Effect of storage site on diameter losses of garlic bulbs at different storage weeks. |

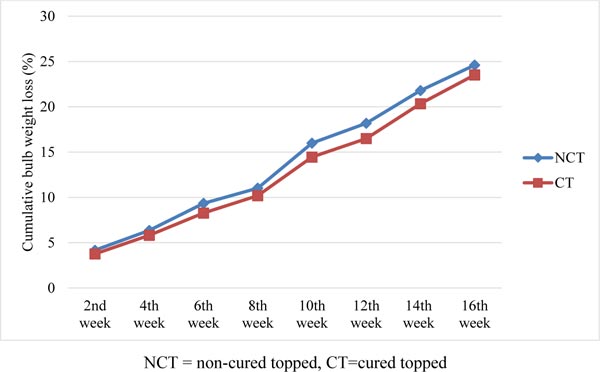

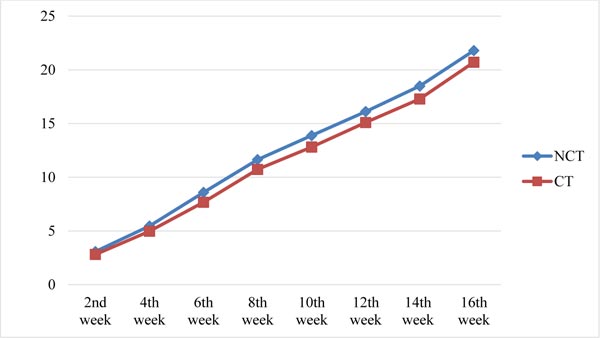

The highest loss in bulb weight and diameter appeared in non-cured topped bulbs, which showed a persistently higher percentage of loss throughout the storage period except for during treatment application (Figs. 7 and 8). This can be explained by the fact that during curing, the thin outer layers of the bulb are dried to form one or more complete dry skins, which act as a barrier to water loss. Curing also dries the necks of the bulbs and makes them tightly closed [5]. Fleshy harvested onions contain 80-90% water according to cultivar, and water removal from the outer skins during curing causes a rapid loss of up to 5% of total weight. However, this loss is more compensated by reduced loss during storage life [4].

|

Fig. (7). Effect of curing on weight losses of garlic bulbs at different storage weeks. |

|

Fig. (8). Effect of curing on diameter losses of garlic bulbs at different storage weeks. |

As bulbs are cured-topped, the metabolic activities will be kept to the minimum since bulbs are at their dormancy that keeps respiration rates low. In comparison for total weight, there was 4.59% to 10.9% more weight loss in non-cured than cured-topped ones during the storage period (Fig. 7). Therefore, cured-topped bulbs were capable of arresting metabolic processes at a minimum rate than non-cured ones with higher moisture content. The least weight and diameter loss may be attributed to the proper drying of the outer scales and formation of the tight neck, checking further escape of moisture and thus reduced the weight loss during storage.

Similar findings were reported by Thompson et al. [20] and Sidhu and Chadha [21], who observed that physiological loss in weight was lesser in cured bulbs during storage. On the other hand, the thick neck with succulent skin of non-cured topped bulbs brought about the maximum physiological weight loss and skin shrinkage, possibly as a result of higher respiration. Rubatzky and Yamagunchi [1] described that during storage, translocations of carbohydrates occur via the stem plate from the outermost succulent swollen scales to inner scales. They further noted that the outermost succulent scale gradually desiccated, becoming a dry protective scale that helped to reduce water loss from inner succulent scales. This process can continue, resulting in an increase in the number of dry outer scales, and in turn, a decrease of an equal number of succulent scales, along with a concomitant decrease in bulb diameter.

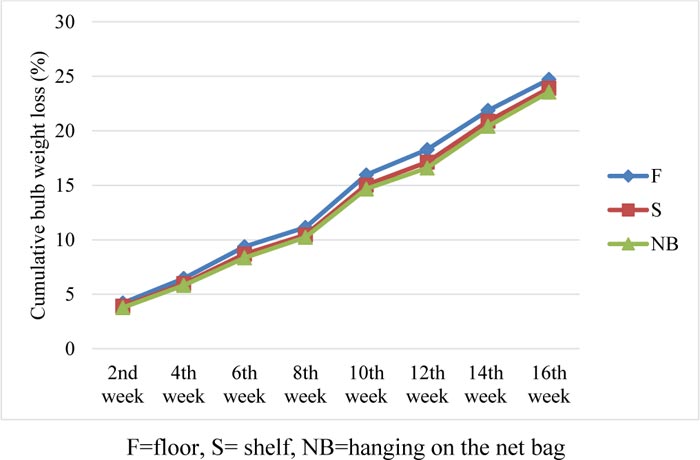

The highest weight and diameter loss were observed in the floor-stored bulbs compared to the shelf and net bag stored bulbs (Figs. 9 and 10). The rate of weight and diameter loss increased with storage time in all cases. This can be explained by the fact that high storage temperature increased moisture loss of bulbs. In agreement with this, Bogevska et al. [22] reported that physiological weight loss in onion bulbs is higher in the traditional open ground method as compared to wooden packed structures ventilated from all sides.

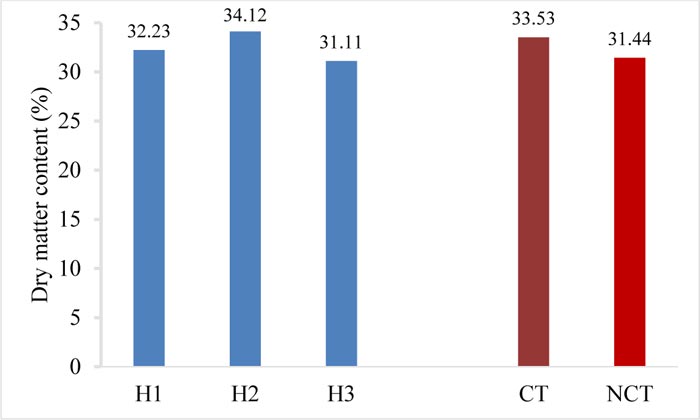

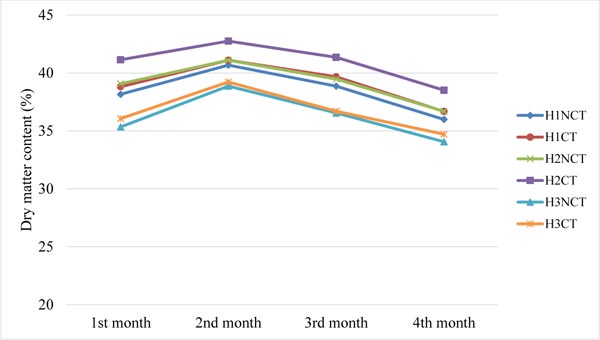

3.3. Dry Matter Content

The highest dry matter percentages at harvest were recorded from bulbs harvested at 80% top fall compared to 60 and 100% top fall harvested bulbs (Fig. 11). On the other hand, at all successive storage months, bulbs harvested at 80% top fall and cured topped showed the highest dry matter percentages. However, the lowest dry matter content at the initial stage and during the storage months was observed in the bulbs harvested at 100% top fall (Fig. 12).

|

Fig. (9). Effect of storage method on weight losses of garlic bulbs at different storage weeks. |

|

Fig. (10). Effect of storage method on diameter losses of garlic bulbs at different storage weeks. |

|

Fig. (11). Effect of harvesting time and curing on percent dry matter content of garlic bulbs at harvest. |

|

Fig. (12). Effect of harvesting time and curing interaction on dry matter content of garlic bulbs at different storage months. |

Garlic plants require optimum time to accumulate photosynthate in their bulbs. As senescence was reached, there was a reduction in their dry matter content, possibly due to loss through respiration or dilution effect. Similarly, Hansen and Henriksen [23] reported that dry matter content increased during the period of bulb development while harvesting later than 80-90% top fall reduced dry matter content and storability. They noted that during the period from 10 to 100% top fall, there was a 44% increase in the total yield of fresh bulbs, but the dry matter content did not change significantly up to 80% top fall, after which a distinct decrease was observed.

The highest dry matter content of bulbs was observed at two months storage and then a gradual decrease until termination of the storage treatment was observed (Fig. 12). The report by Hansen and Henriksen [23] also showed a slight increase in a dry matter due to loss of moisture from the outer surface, whereas the reduction corresponded well to hydrolysis of fructans and termination of the dormancy period where the bulbs began to sprout. Pak et al. [24] described the dry matter of shallot consisted of 70-85% carbohydrates, mainly fructans, glucose, fructose, and sucrose. They indicated that through storage, fructans were gradually hydrolyzed to fructose, resulting in the increase of dry matter at initial storage weeks. At the time of sprouting, sucrose was synthesized and transported to the sprout and basal plate for growth. Similarly, Hansen and Henriksen [23] observed a decrease in dry matter content with storage time and the concentration of fructans.

The increase in dry matter content by curing treatment could be mainly due to excessive moisture loss from the outer skin during curing. Currah and Proctor [25] indicated that such loss could reach up to 5% of the total fresh weight. Even though the loss of moisture could occur from bulbs while curing, this loss could be compensated for the transport of materials from the leaves to the bulbs during the curing process of bulbs with their tops. After two months of storage, a reduction occurred in the dry matter content. Rubatzky and Yamagunchi [1] indicated that during storage, there was a loss in dry matter and moisture as a result of translocation of carbohydrates for the respiration process, which is in agreement with the current findings.

Similarly, Benkeblia et al. [26] found the respiration rate of onions after two months of storage was 0.21 and 0.32 mmol kg-1h-1 at 20°C for unsprouted and sprouted onions, respectively, which was accompanied by loss of the dry matter content of the bulbs.

|

Fig. (13). Effect of harvesting time and curing interaction on the sprouting percentage of garlic bulbs at different storage weeks. |

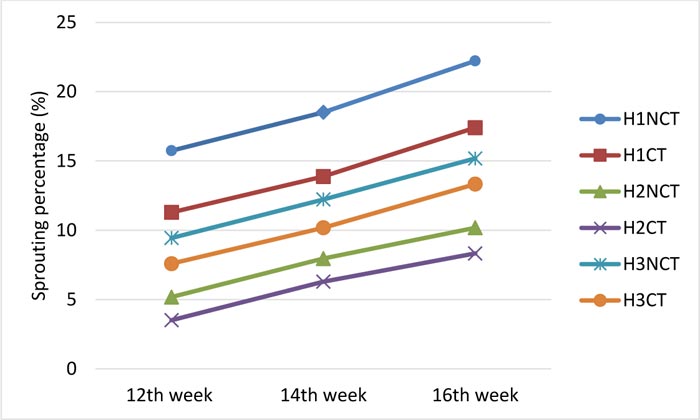

3.4. Sprouting

The highest incidence of sprouting was recorded in the treatment combination of 60% top fall harvest and non-cured bulbs, while the least was observed at 80% top fall harvest and cured bulbs for all successive storage weeks (Fig. 13). Bulbs that are harvested immaturely may take longer than those harvested after maturity to dry properly for storage, and if the necks are yet soft, the inner leaves may still be growing and will continue to elongate from the topped bulbs [27].

There was also a report by Bottcher and Kolbe [28] that showed late harvesting (90% or more tops) of European storage type onions resulted in increased sprouting and rooting, whereas the time for sprouting of bulbs was increased between 50-80% top fall harvest. While curing treatment allows bulbs to develop tough skin that limits the exchange of gas with the external environment by shrinking and closing the neck so that oxygen required for shoot growth and emergence can be minimized [4].

The onset of dormancy is thought to be caused by translocation of growth inhibitory substances from the leaves to the bulbs as crops matured and cured attached with tops [29]. Furthermore, Kielak and Bielinska-czarneck [30] indicated that for bulbs cured while attached with tops, there would be the transport of inhibitory materials like abscisic acid from the leaves to the bulbs. Stow [31] also found a rise in inhibitor concentration of the leaves of onions approaching maturity and showed that defoliation at this stage shortened dormancy.

According to Isenberg et al. [32], abscisic acid was identified but accounted for only 10-20% of the growth inhibitory activity, whereas in the subsequent storage, there was a progressive decline in inhibitor activity of the bulbs, followed by an increase first in cytokines and then in gibberellins and auxin activity, which are responsible for sprouting. Swift [7] also found that curing reduces the occurrence of sprouting by reducing the respiration rate of the bulbs and allows the development of natural dormancy that helps in long-term storage.

Bulb sprouting increased with an increase in storage duration to 16th weeks. Benkeblia and Selselet-Attou [33] also showed that the dormancy period in onion bulbs disappears progressively with the passing of storage time. The increase in bulb sprouting with storage duration could be associated with the decrease in the bulb’s dry matter and total soluble solid content. In addition, Wheeler et al. [34] showed that the lower levels of total water-soluble solids in the center of bulbs as storage time progresses are the main cause of sprouting.

CONCLUSION

Identification of the optimum time of harvesting, curing, and storage methods are among the principal factors to be considered in relation to the garlic shelf life. During the storage period of 120 days, the maximum values of dry matter (38.51%) were observed in bulbs harvested at 80% top fall and cured topped. The minimum bulb weight loss was recorded in bulbs harvested at 80% top fall (22.10%), cured topped bulbs (23.52%), and bulbs stored on a shelf or in net bag and bulbs stored at Haramaya (20.95%).

The diameter loss was also minimum in bulbs harvested at 80% top fall (18.88%), cured topped bulbs (20.71%), bulbs stored on a shelf or in a net bag, and bulbs stored at Haramaya (15.25%). The least number of sprouted bulbs (8.33%) were recorded in bulbs lifted at 80% top fall and cured topped. Therefore, bulbs lifted at 80% top fall, cured topped, shelf, or net bag stored at Haramaya would be recommended as the best practice to maintain quality and prolong the shelf life of the ‘Tseday’ variety.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

Not applicable.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

Not applicable.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Ethiopian Ministry of Education, Debre Berhan University, and Haramaya University are acknowledged for their support.

REFERENCES

| [1] | Rubatzky VE, Yamaguchi M. World vegetables, principles, production and nutritive values.1997; 843. |

| [2] | Kamenetsky R. Garlic: Botany and Horticulture J Janick (eds) 2007; : -. |

| [3] | Hickey M. Growing garlic at New South Wells (NSW). Prime fact 2006; 269: 1-6. |

| [4] | Currah L, Rabinowitch HD. Allium crop science: Recent advances 2002; 329-515. |

| [5] | Gubb IR, Tavis MSH. Onion preharvest and postharvest considerations.Allim Crop Science 2002; 234-65. |

| [6] | Apeland J. Effects of scale quality on physiological processes in onions. Acta Hortic 1971; (20): 72-9. |

| [7] | Swift E. Harvesting and storing onion and garlic 1997. |

| [8] | Peiris KHS, Mallon JL, Kays SJ. Respiratory rate and vital heat of some specialty vegetables at various storage temperatures. Horttechnology 1997; 7: 46-9. |

| [9] | Hannan RM, Sorensen EJ. Crop profile for garlic in Washington. Washington State University Cooperative Extension. MISC0369E. 2002; 14. |

| [10] | Cantwell MI. Garlic Recommendations for maintaining postharvest quality 2004. Available at: http:/postharvest.ucdavis.edu/Produce/ProduceFacts |

| [11] | Brecht JK. Underground storage organs.Postharvest physiology and pathology of vegetable crops, II 2003; 625-47. |

| [12] | Vazquez-Barrios ME, Lopez-Echevarria G, Mercado-Silva E, Castano-Tostado E, Leon-Gonzalez F. Study and prediction of quality changes in garlic cv. Perla (Allium sativum L.) stored at different temperatures. Sci Hortic (Amsterdam) 2006; 108: 127-32. |

| [13] | Diriba S, Nigussie D, Kebede W, Getachew T, Sharma JJ. Postharvest quality and shelf life of garlic bulb as influenced by storage season, soil type and different compound fertilizers J Posthar Tech 2013; 1(1): 069-83. |

| [14] | Getenesh N, Ali M, Temesgen M. Effect of curing and top removal time on quality and shelf life of onions (Allium Cepa L.) Glob J Sci Front Res: D Agricul Veter 2015; 15(8): 26-36. |

| [15] | Getachew T, Asfaw Z. Achievements in shallot and garlic research report 2000. |

| [16] | Waskar DP, Khedlar RM, Garande VK. Effect of postharvest treatment on shelf life and quality of pomegranate in evaporative cool chamber and ambient conditions. J Food Sci Technol 1999; 2(36): 114-7. |

| [17] | Gomez KA, Gomez AA. Statistical procedures of agricultural research 1984; 680. |

| [18] | Davis HR, Isenberg MR. Storage recommendation for northern grown onions.Cornell university extension bulletin No 148 1978; 214. |

| [19] | Biswas SK, Khair A, Sarkar PK, Alom MS. Yield and storability of onion (Allium cepa L.) as affected by varying levels of irrigation. Bangladesh J Agric Res 2010; 35: 247-55. |

| [20] | Thompson AK, Booth RH, Proctor FJ. Onion storage in tropics. Trop Sci 1972; 14(1): 19-34. |

| [21] | Sidhu AS, Chadha ML. Studies on the storage life of kharif onion. Indian Food Pack 1986; 40(1-2): 69-72. |

| [22] | Bogevska Z, Agic R, Popsimonova G, Davitkovska M, Iljovski I. Physiological loss during storage of sweet onion in Republic of Macedonia. Poljopr Sumar 2014; 60(4): 49-154. |

| [23] | Hansen SL, Henriksen K. Increasing the dry matter production in bulb onions (Allium cepa L.). Denmark Department of Fruit, Vegetable and Food Science 2001; 2: 147-52. |

| [24] | Pak C. Van der plas LHW., de Boer AD. Respiration and ethylene evolution of certain fruits and vegetables in response to carbondioxide in controlled atmosphere storage. J Food Sci Technol 1995; 30: 29-32. |

| [25] | Currah L, Proctor F J. Onions in the tropical regions. Natural Resource Institute 1990. Bul. No. 35. |

| [26] | Benkeblia N, Varoquaus P, Gouble B, Selselet-Attou G. Respiratory parameters of onion bulbs (Allium cepa) during storage. Effects of ionizing radiation and temperature. J Sci Food Agric 2000; 80: 1772-8. |

| [27] | Jones HA, Mann LK. Onions and their allies: Botany, cultivation, and utilization 1963; 285. |

| [28] | Bottcher H, Kolbe G. The effect of mineral fertilizers on the yield, quality and storage properties of onion. Archifar Gartenban (German) 1975; 23(5): 307-19. |

| [29] | Komochi S. Bulb Dormancy and Storage In: Tabinowitch HD, Brewster JL, Eds. 1990. |

| [30] | Kielak E, Bielinska-Crarneck M. Effects of length of drying on hormone activity in onion (Allium cepa L.) during storage. Proceedings of the IV international symposium of plant growth regulators 1987; 155-9. |

| [31] | Stow JR. The effect of defoliation on storage potential of bulbs of the onion (Allium cepa L.). Ann Appl Biol 1976; 84: 71-9. |

| [32] | Isenberg FMR, Thomas TH, Pendegrass AM, Abdel-Rahman M. Hormone and histological differences between normal and maleic hydrazide treated onions stored over winter. Acta Hortic 1974; (38): 95-125. |

| [33] | Benkeblia N, Selselet-Attou G. Effect of low temperatures on changes in oligosaccharides, phenolics and peroxidase in inner bud of onion (Allium cepa L.) during break of dormancy. Acta Agriculturae 1999; 49: 122-4. |

| [34] | Wheeler TR, Daymond AJ, Ellis RH, Morison JIL, Hadley P. Postharvest sprouting of onion bulbs grown in different temperature and carbon dioxide environments in the UK. J Hortic Sci Biotechnol 1998; 73: 750-4. |